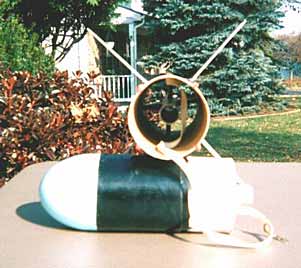

Scratch Scrap-Rocket 2 (SR2) Original Design / Scratch Built

Scratch - Scrap-Rocket 2 (SR2) {Scratch}

Contributed by Dick Stafford

| Manufacturer: | Scratch |

Brief:

Brief:

The SR-2 was built in the late 80's by my son (~7 years old at the time). I am

providing this review as an example of using scrap materials and to document an

approach to parachute deployment that does not require wadding.

Construction:

Parts list (items A-L shown on diagram):

- L'Eggs pantyhose egg (large portion)

- 2 ¾" wrapping paper tube (3" section)

- coupler tube made from wrapping paper tube (5 1/2" section, 2" shoulder exposed)

- bulkhead made from 3/16" balsa

- BT-20 balsa coupler (mates with BT-20 stuffer tube), Estes

- main airframe, 9 ¾" section of wrapping paper tube

- launch lug, Estes

- hardwood stringer (4), 1/16" square, 9 ¾" long

- hardwood stringer (4), 1/16" square, 8" long

- plastic fins (4), 1/16" thick (styrene?)

- balsa spacers (4), 3/16" x 1" x 3"

- BT-20 motor/stuffer tube, 8 ¾", extends from 1" below main airframe

- elastic shock cord, 12"

- parachute, 12" or larger

- engine block made from ¾" section of used 18mm casing

- 1" section of dowel

- Snap swivel tied to shock cord.

The rocket body consists of a BT-20 tube centered in the main airframe (refer to diagram). The nose cone assembly includes a bulkhead which seats in the BT-20 tube. The chute is packed between the BT-20 tube and the airframe, and is not directly exposed to the ejection gasses. Some of the gasses may come in contact with the chute, but this design has worked several times without incident. I think I invented this method, but it has been a while, and the memory is the second thing to go (and I don't remember the first one!)

Make the coupler tube by cutting a section of the wrapping tube lengthwise and turning in on itself. Glue this into the forward tube so that 2" extends out the rear and ?" extends out the front. Cut the bulkhead from balsa stock and glue the BT-20 coupler on its center. The balsa may be too weak to hold a hook-eye. Instead, punch a hole in the bulkhead midway between the BT-20 coupler and the edge of the coupler.

Feed the shock cord though the hole, tie it to a small section of dowel and glue the dowel to the bulkhead. Glue the bulkhead in the rear and the nose cone to the exposed front end of the coupler (use CA for the latter).

Wood stringers were added because the tube that was used was

very weak. These would not be required for, say, a mailing tube. Mark 8 evenly

spaced parallel lines around the tube using your favorite method. Glue the

stringers on, alternating short and long lengths.

Wood stringers were added because the tube that was used was

very weak. These would not be required for, say, a mailing tube. Mark 8 evenly

spaced parallel lines around the tube using your favorite method. Glue the

stringers on, alternating short and long lengths.

Cut four pieces of balsa to the dimensions indicated. Mark the BT20 tube and glue the spacers on. When dry, test fit the assembly into the rear of the airframe, making sure it mates with the nose cone assembly. With the nose cone assembly installed, glue in the motor tube assembly (should extend ~1" from the rear of the airframe).

Cut the fins to the dimensions shown. I used scrap pieces of plastic but balsa can be substituted. Glue the fins to the long stringers and a lug to one of the short ones. Feed the shock cord through a snap swivel and connect it to the inside of the airframe. I used the Estes folded paper method.

I left the nose cone its natural baby blue and the fins their natural gray. The rest is a hodgepodge. Use what you got! Buy fresh paint for a more 'serious' rocket.

Flight:

This rocket made several flights on C6-5s but a shorter delay is probably

preferable. Performance was similar to a 18mm Fat Boy.

I folded the chute and wrapped the shroud lines around it. It was placed between the stuffer tube and the main airframe. The shock cord then was laid in next to the chute. The chute attached ~2 inches from where the shock cord attaches to the nose cone assembly.

Summary:

The main Pros of this rocket are: it was cheap and fun to make; it requires no

wadding and is easy to prep.

The only Con I can think of is that the plastic fins may be prone to breakage. (I flew this rocket on soft grass.)

If I were to start over, it would have FatBoy-style fins.

Sponsored Ads

|

|