Scratch SuperFly Original Design / Scratch Built

Scratch - SuperFly {Scratch}

Contributed by Dave Brunsting

| Manufacturer: | Scratch |

Brief:

Brief:

This is my first foray into the world of APCP from 3 years ago. In 2005 I went to scratch build one of my most reliable and awesome rockets to date. It is an awesome F and G burner and has yet to let me down.

Construction:

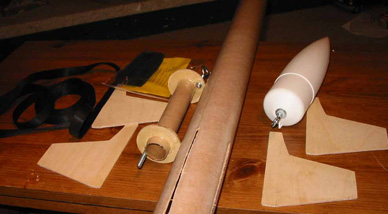

- 34" 2.6" phenolic tube

- 2.6" Nose cone - Purchased from RAH - not sure what brand it was anymore

- (2) 29mm centering rings

- 29mm tubing

- 8" of 1/4" all-thread

- 10" of 1/2" tubular nylon

- 1/4" eye bolt with 2 washers and 2 nuts

- A bunch of 1/8" birch aircraft plywood

- (2) 1/4" launch lugs

This build was very easy but I made it tough because I over-thought every move since this was the first time I used things like epoxy, plywood centering rings, etc., on a rocket. Originally, I thought I could make this light enough to fly on E's but as the build progressed with my amateur building techniques I soon realized it was going to weigh way too much for that to happen. I settled for F's and G's.

This build was very easy but I made it tough because I over-thought every move since this was the first time I used things like epoxy, plywood centering rings, etc., on a rocket. Originally, I thought I could make this light enough to fly on E's but as the build progressed with my amateur building techniques I soon realized it was going to weigh way too much for that to happen. I settled for F's and G's.

Since it's been three years since I built it I am a little fuzzy on the sequence. First came cutting the body tubes for the fin slots. I used a circular saw with a plywood blade. Bad idea. The slots wound up being very very frayed and a pain to finish.

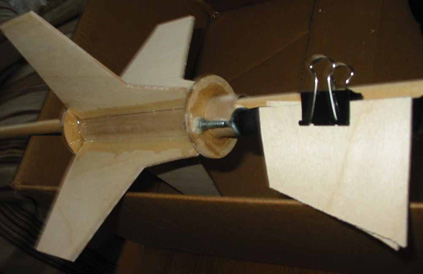

I also used the circular saw on the fins. It wasn't too bad I guess but they wound up being okay. Then I cut the 29mm tubing about 1 1/2" longer than the fin root to make sure I had enough tube to glue the fins. Using CA glue the fins were tacked onto the MMT tube and the centering rings on either of the fin ends as well.

I also used the circular saw on the fins. It wasn't too bad I guess but they wound up being okay. Then I cut the 29mm tubing about 1 1/2" longer than the fin root to make sure I had enough tube to glue the fins. Using CA glue the fins were tacked onto the MMT tube and the centering rings on either of the fin ends as well.

I applied 30 minute epoxy to all the internal fillets. Once dried, a hole was drilled in the aft centering ring for the 1/4" all thread. This is for the motor retention. The all thread was epoxied throughout between the centering rings. No way that thing was going to move. I could put a 29mm I and have it cato and by golly the rocket might be in shreds but that all thread would still be attached to the 29mm tube.

In the forward centering ring, the 1/4" eye bolt was attached and epoxied into place. This was for the shock cord. The shock cord was lapped over on itself and sewed the cord together.

In the forward centering ring, the 1/4" eye bolt was attached and epoxied into place. This was for the shock cord. The shock cord was lapped over on itself and sewed the cord together.

Once dried I slid the entire fin can contraption into the fin slots. Everything fit well and the fillets on the outside of the BT. On the outside of the BT I glued 2 1/4" launch lugs about 12" apart.

Finishing:

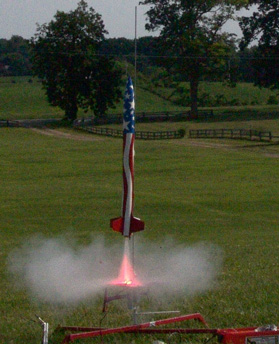

Finishing only included your basic rattle-can paint. Kilz spray-on primer and then Krylon colors. The first paint job was this horrific red/yellow/white pain on the eyes. After tolerating this for about a year I sanded off that noise and applied a real paint job with a patriotic theme. White stars of different sizes on a blue field on the front with wavy red and white stripes down the side. To finish it off I cut out a stencil with the word "SUPERFLY" using the Weltran font printed off of my computer.

Flight:

Flight:

Here are the motors that SuperFly has flown on the best I can remember (I may not have the delays right):

- F20-4

- F25-4

- F40-4

- G33-7

- G64-8

- G71-8

- G77-7

- G80-8

Every flight was great. I won't do an F20 again unless it is dead calm because it weather-cocks quite a bit. One of these days I am going to get a 29/180 case for this and really have some fun with it. It flies very similar to a PML IO but not quite as high.

I usually use a 24" chute for recovery which brings it down REALLY fast but I launch on a typically wet and soft corn field. I have also used a 30" which would be better for harder recovery areas.

I usually use a 24" chute for recovery which brings it down REALLY fast but I launch on a typically wet and soft corn field. I have also used a 30" which would be better for harder recovery areas.

Summary:

PRO: I built this thing like a tank. It keeps taking abuse and coming back for more.

CON: The motor mount. I really wish I would have built this with a 38mm motor mount. Anyone building a rocket that will fly regularly on G's should consider this. There are a whole host of 38mm G motors out there from CTI and AT - not to mention the baby H's for when you are brave. You can always adapt down - not up.

Sponsored Ads

|

|