Brief:

Brief:

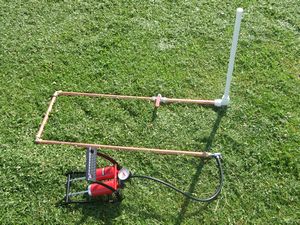

There are several air pressure rockets on the market that either use an air chamber that you pressurize by a hand or foot pump and the rocket fires by a release mechanism or allows pressure to build up until it overcomes the friction holding the rocket on the launcher. This one is a variation on this idea. A foot pump builds the pressure inside some copper tubes and is then released via a ball valve. This allows a pressure of up to 60 PSI and can launch a rocket to over 400ft.

I cannot take credit for the design; a work colleague that had attended an Association of Science Education and Institute of Physics meeting where the complete kits were handed out gave it to me. You can see the PDF of the build via this link.

Construction:

You will need:

- 85cm x 22mm copper pipe

- 55cm x 22mm copper pipe

- 2 30cm x 22mm copper pipe

- Pipe cutter

- 2 22mm elbow joints (compression)

- 22mm to 15mm reducer (compression)

- PTFE (plumber's) tape

- 22mm ball valve (compression)

- Snap on pneumatic valve

- Plumber's wrench

- 55cm x 22mm plastic pipe

- 35cm x 22mm plastic pipe (rocket tube mandrel)

- 22mm plastic elbow joint (push fit)

- A4 paper

- cellotape

The copper pipes can be made out of one 2m length of pipe. You have to use the pipe cutter tool to get a good edge on the pipes and it is a lot quicker to use than a hack saw.

- Put the tire valve into the 22mm to 15mm reducer. Remove the olive from the 15mm end and then pull the valve through from the 22mm end so the valve is sticking through the 15mm end. It needs a good pull and you should feel it click into place. I was doubtful to how air tight this would be and thought about adding some glue to the end but so far there has been no leaks.

- Add the 85cm length of pipe to the reducer. Unscrew the nut and slide that over the pipe followed by the olive, add PTFE tape around the thread, and then screw the nut back on, keeping the pipe in. (As the nut tightens the olive gets squashed forming a air tight seal holding the pipe in place.)

- Then add an elbow joint on the end.

- To the elbow joint add the 30cm pipe.

- To the other end of the pipe add another elbow joint

- To the elbow joint add the 55cm pipe.

- To the end of the 55cm pipe add the ball valve, it does not matter which way it goes on.

- On the other side of the ball valve add the 30cm pipe.

- As this end will not be pressurized, the next joint is the plastic push fit elbow and plastic pipe. The added advantage is that the push fit joint is airtight and rotates allowing you to move the launch arm.

To avoid embarrassment on the launch field, test the launcher by pressurizing the launcher to 4 Bar or 60 PSI. There should be no "hissing" or drop in pressure. If there is, then the joints need to be tightened.

Using the 35cm plastic pipe as a mandrel, wrap a sheet of A4 (US letter is fairly similar) paper around the pipe and fasten this down with cellotape. The tube needs to be air tight so run a length of tape down the seam.

The nose cone can be made to what ever degree of finish you want. The instructions I had were to simply tape the ends together. Again, adding more tape to make it air tight. You could make a cone if you wish, but the rocket will be recovering via ballistic recovery so nothing too heavy or pointy! The fins are added on the back and that again is entirely up to you to the amount and shape. So far I have made four rockets. The first was a prototype, just plain white with four foam card fins. Second one was a 3 card fin rocket coated in purple prismatic book covers with a pointed nose cone made for my son William. The third was a 3 card fin rocket coated in green prismatic book covers with a foam block for its nose cone. The fourth was a 4 card fin rocket with the fins angled at 30 degrees to make the rocket spin, but there was no nose cone to speak of so the top is flat.

CP and CG considerations: as there is no motor, the rocket is a tube with the CP and CG in the middle. Taping the nose cone end lifts the CG a bit, adding fins lowers the CG and CP. If the fin material is heavy then the CG will drop too much. So its best to stick with paper/card fins that are at the base of rocket or even better, swept back. I would avoid adding mass to the nose cone to lift CG as the rocket is going to be coming in ballistic.

PROs

- Very cheap launches (free). Given the present financial situation and the price of a pack of C motors in the UK being near £10, this helps bulk out the launch day.

- The rockets can be experimented with, making this excellent for school and youth group activities. Lots of competitions can be run: closest to the spot, longest in flight, furthest flown, and best looking, and all very cheaply.

- I think it's better than the stomp rockets on the market, it is more adult, the rockets go higher.

CONs:

- Quite expensive to set up, cost me just under £50.

- The recovery system is non-existent. And I fear that someone will start adding metal mass to the nose cone end and start flying in crowded parks.

Flight:

I've flown each rocket 3 times each, all at 60 PSI.

The white prototype flew the best getting to about 250 feet, but the body tube crimps a bit on landing.

The second (William) with the pointy nose cone got to about 150 feet. The extra mass of the covers really does hamper altitude, and the nose cone get squashed flat on landing.

The third (SKY) gets to about 120 feet. No damage.

The fourth (TURN ABOUT) spins really well on the way up and down and gets to just under 150 feet, was slower landing, and has received no damage.

|

|