| Manufacturer: | Modification |

Brief:

Brief:

I changed the motor mount (MMT) to a 38mm from stock 29mm and used a GROOVE-LOK from Giant Leap Rocketry to anchor fins to the MMT. I used 0.187 plywood bulkheads and centering rings throughout. I added an electronics/payload bay to the sustainer section. Changed out the chute for a larger one and added a Aero Pac Quick-Change motor retainer.

Modifications:

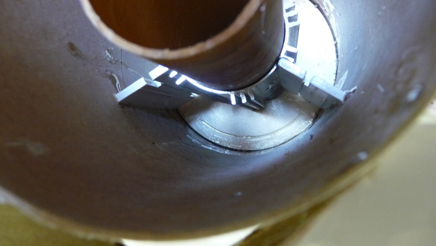

I had to reduce the tang on the stock plastic fins in order to accommodate the larger MMT and the GROOVE-LOK. I used a power miter saw to cut them slightly larger than needed, then fit them with a file. Care must be used not to let the plastic piece get too hot and start to melt - just take a bit at a time. I bought a 6" GROOVE-LOK but cut it to fit between the two rear centering rings that encased the fin tangs (picture). The fins were 6-filleted with 30-minute epoxy.

I replaced the stock 42" chute with a 50" one due to the increased weight of the mods and I used a Nomex piece in lieu of the baffle that was sent to use with the stock MMT.

Construction:

Construction:

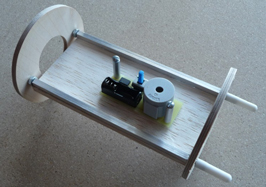

The MMT is a phenolic 38mm x 18" tube from Giant Leap to replace the paper 29mm factory unit. Main coupler was replaced with a phenolic one from Giant Leap and epoxied to the booster rather than the sustainer to better protect the booster lip on ejection. The e-bay was scratch built from a phenolic coupler and plywood bulkheads; the sled slides on 8-32 all-thread and is made from 1/8" balsa plywood and two pieces of aluminum 3/16" square tubing.

I used the GROOVE-LOK so that once I set one of the fins in place, the alignment of the others was a snap, plus the individual groove rails gives the fin a nice sturdy mount to complement/strengthen the expoxy fillet. The exterior fin root bulges in the middle making the filleting process a bit more difficult to make it look good, but I had it down by the third fillet.

I used the GROOVE-LOK so that once I set one of the fins in place, the alignment of the others was a snap, plus the individual groove rails gives the fin a nice sturdy mount to complement/strengthen the expoxy fillet. The exterior fin root bulges in the middle making the filleting process a bit more difficult to make it look good, but I had it down by the third fillet.

The overall kit went together easily and the instructions were clear. I filled the airframe tube spirals with Elmers wood filler and acheived a decently smooth exterior with one application and sanding. I did not use the included decals, but rather made my own. The finish was gloss white. Looked really nice sitting on the launch pad.

Flight:

The stock kit called for G motors, but going from the 32 oz. stock dry weight to the final 56 oz. called for typically a bit more power. I bought a G38, a G40 and a G77 with the kit before I decided to modifiy it. The G38 and G40 RockSim'd (I have a revised .rkt file I will email) out as a crash and a 25' recovery, whereas it said that the G77 should put it to 400'+, which is what happened.

The first flight was on the G77-4 and it flew perfectly straight with the motor ejection occuring right at apogee and no roll to speak of. The bottom of the booster tube sits about a 1/2" below the bottom of the fins, so on a perfectly still day like we had, the rocket comes down on the tube. It crinkled just a bit on one edge. I saw in an earlier article that someone had reinforced that area with a piece of coupler tube. I intended to do so but forgot - wished I had, but I will reinforce it somehow in the future before it flys again.

The first flight was on the G77-4 and it flew perfectly straight with the motor ejection occuring right at apogee and no roll to speak of. The bottom of the booster tube sits about a 1/2" below the bottom of the fins, so on a perfectly still day like we had, the rocket comes down on the tube. It crinkled just a bit on one edge. I saw in an earlier article that someone had reinforced that area with a piece of coupler tube. I intended to do so but forgot - wished I had, but I will reinforce it somehow in the future before it flys again.

So, since I was succesful on the test flight with the G77, I decided to put a small H motor in it and do my Level 1 Tripoli certification flight. I put an H128 but the motor reload kit had the medium, or 10 second delay. rockSim said I needed a 6-7 second delay, so I drilled out a bit of the delay during assembly. The H128 worked as sim'd and went about 850' with the ejection once again right at the top of a very straight, no-roll flight. Level 1 accomplished! The booster hit on the hard-pack desert road and worstened the crinkle, so I definitely need to add something there or go to my 58" chute, or both.

Summary:

Great flyer as everyone else said and the stock components were very nice as far as quality, I just wanted something a bit stronger in the bottom since I want to see about it going to 5K', which I will try next time out.

Related Products

Sponsored Ads

|

|