Scratch Senior Prank Original Design / Scratch Built

Scratch - Senior Prank {Scratch}

Contributed by Ray King

| Manufacturer: | Scratch |

Brief:

Brief:

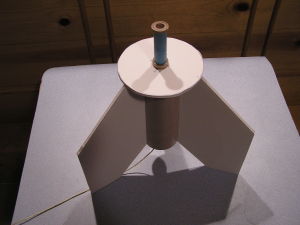

The Senior Prank was a brainstorm while I was in my favorite room of the house trying to come up with a cleaver submission to the Odd-Rocket Contest. I began focusing on the toilet paper sitting next to me on the wall for a couple of reason, but I won't go into that. I realized that although I had seen a number of rockets made from the toilet paper tube, I had never seen one with the toilet paper still on the tube so I decided I would build a rocket that could launch 3 rolls, eject them and TP the launch area.

Construction:

The parts list:

- 1 Sheet of Foam Poster board (2' x 3')

- 1 Sheet (14" x 14") Std Poster board or card stock

- 1 8" BT-50 Tube

- 1 24" BT-50 Tube

- 1 BT-50 Centering Ring (Internal)

- 1 7.25" BT 80 Tube

- 2 Centering rings (BT80 to BT50)

- 1 18mm Engine Tube

- 2 Centering rings (Engine tube to BT 50)

- 1 Used 18mm Engine casing

- 36" 400# Kevlar Shock Cord

- 24" x 3/8" Elastic Shock Cord

Engine Mount: The engine mount is made from the 8" BT-50 tube with the BT-80 to BT-50 centering rings mounted. The ring closest to the engine is mounted 1.25" from the end. The other one is mounted 1.5" inches from the opposite end. Before mounting, I notched the top one with a hole punch near the inside diameter to allow the shock cord to pass through. In addition, I punched a hole in each centering ring roughly in the center of each ring. These holes were used for the launch rod so they had to line up when attached to the BT-50 tube. The last step was attach the elastic shock cord. I tied a loop in the end and then did a full wrap around the tube and pushed the other end through the notch in the upper centering ring. I glued the full wrap of elastic to the tube to ensure it does not get pulled through.

Fins Construction: Fins were cut from foam poster board. See Fin Template.

Main Body Tube Assembly: I started by cutting the disk (Template A) out of foamboard and then cut 3 disks (Template B) from the foamboard.

I mounted the fins to the BT-80 tube 120 degrees apart. Next, I mounted the disk (Template A) to the top of the BT-80 tube and reinforced the all the joints with bead of epoxy. Then, I glued the 3 disks together and wrapped the end of the Kevlar shock cord halfway around the 3 disk assembly and glued it in place. The cord should only cover the center hole on one side the other side should be uncovered. This sub-assembly was inserted into the main body tube, and I applied a liberal amount of glue to the side of the sub-assembly where the Kevlar shock stretches across the hole. The next step was adding a bead on the inside of the tube and slid the sub-assembly down the tube until it bottoms. The Kevlar shock cord extended out the bottom of the tube. Finally, I cleaned up any excess glue on the inside of the body tube and attached the Kevlar and Elastic shock cords.

Next, I epoxied 2 centering rings to an 18mm engine tube one on each end then glued a used engine into the engine tube. I epoxied the engine tube sub-assembly to the center of the disk mounted on top of the main body tube assembly.

Lastly, I glue the 24" BT-50 tube to the used engine sub-assembly and glued the centering ring inside the top of the BT-50 tube. This is used to provide some rigidity at the top of the top.

Nose Cone: Start by cutting the disk (Template A) out of foam board then cut the nose cone out by cuttimg out a 13 inch circle from regular poster board, mark the center, and then cut 120 degrees out of the circle. Form the poster board into a cone and glue the seam. I glued the foam disk to the underside of the cone, making sure the launch rod holes line up. I suggest adding a bead of epoxy around the joint between the cone and foam board and a thin coating on the point of the nose to protect it during landing. Finally, I added a reinforcing ring where the launch rod comes out of the cone.

Finishing:

This rocket has a no frills paint job of Blaze Orange on the nose cone and lower section.

Flight:

This is a little tricky so follow along carefully. First, I installed the selected engine into the engine tube sub-assembly, taping it in place. Then I added some wadding (dog barf) to the opposite side of the engine tube. The elastic and Kevlar shock cords were stuffed in on top of the wadding. I rolled the parachute and place it between the 2 centering rings then slid a spare launch rod through the holes in the centering ring of the engine sub-assembly making sure it slid nicely. Next, I slid the launch rod through main body tube assembly and inserted the engine sub-assembly into the main body tube. I checked the rod to make sure it could still move freely. Then the toilet paper was placed over the tube and rod followed by installing the nose cone. I checked again to make sure that the rod could move freely. Finally, I mounted the rod onto the launcher, added the igniter, and got ready for launch.

This is a fun rocket to fly--I have found that D engines don't really have enough thrust, but with a D12-0, the rolls eject on an upward trajectory which is pretty cool. Launching with an E9-4 works pretty well.

Summary:

PROs: Rocket flies well, pretty easy to build, and a great crowd pleaser.

CONs: Needs more power--D and E motors just don't get the altitude I would like to see.

|

|

Sponsored Ads

|

|

Lester Anderson (February 10, 2013)

As fun as this looks, didn't the RSO or property owner get upset about the littering on the property?