| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstar_borderstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | The Launch Pad  |

| Style: | Scale |

Brief:

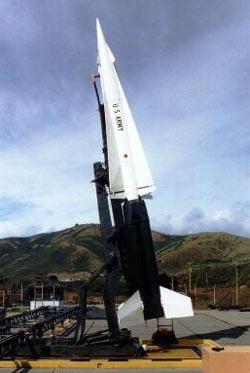

This is not a kit; it is a plan pak that is a scale model (about 1:10) of the US Army Nike Hercules surface to air missile from The Launch Pad. The project is a two-stage rocket that utilizes parachute recovery for both the booster and sustainer. The booster is a cluster of four D12 motors and the sustainer is a single D12 motor.

This is not a kit; it is a plan pak that is a scale model (about 1:10) of the US Army Nike Hercules surface to air missile from The Launch Pad. The project is a two-stage rocket that utilizes parachute recovery for both the booster and sustainer. The booster is a cluster of four D12 motors and the sustainer is a single D12 motor.

Construction:

There are four body tubes in the booster and one for the sustainer. The plans call for you to roll your own tubes out of posterboard. Since it is a four motor clustered booster you have to fabricate or obtain 8 centering rings for the booster and two more for the sustainer. The 24mm motor tubes were all just long enough for an Estes D12 except for the switch tube, which has a piston in if for the sustainer ignition. I used 3 feet of 1/4" elastic shock cord for both the booster and sustainer. The nose cone is the Estes Phoenix which requires a bit of modification by attaching a point onto the otherwise ogive Estes Phoenix NC.

Defining pros and cons is a difficult task because it is a real butt-kicker to build, which is not necessarily a bad thing. That said, it has clearly been the most fun and challenging to build and fly. I chose the plan pak for two reasons: First, I wanted something with a degree of difficulty beyond anything I've ever done. Second, I wanted a Nike Hercules because it has to be the coolest rocket I've ever seen. After talking to quite a few people and describing the project, I received all sorts of advice on modifications I should make. After seriously considering most of them I decided that I was going to build it stock.as close to the way Chuck describes in the plans as possible. Intent on doing this, I tried to roll my own tubes (as per the instructions). After two rounds of attempts I gave up and just purchased the sustainer tube (Estes 2.6") and a buddy of mine gave me some of his old Centuri 2" stock for the booster. As a result my kit ended up a bit heavier than was originally intended. I added some weight in the nose to compensate. I calculated the CP on the sustainer by itself and put enough weight in the nose for a 1.50 caliber static margin.

The major pro about the kit is the instructions themselves¬hing short of impeccable. Before I started this project I had built the Phoenix kit by TLP and I believe that certainly helped. There were only two places where I got a bit stuck in the instructions. Other than that Chuck Barndt has obviously taken the time to write it well. The diagrams are also quite helpful. Another plus is the ease of acquiring most of the parts to build the rocket, mostly from Hobby Lobby and a few odds and ends at the local hobby shop.

The worst experience I had in building this rocket was procuring an Estes Phoenix nose cone without actually dropping down the $22 to buy the kit. After weeks of trying to get Estes just to answer the phone and then promising to send it to me I found George Bartzokis on rec.models.rockets from Needham, MA who said he'd give me his old one. Thanks George! By the way, I'm still waiting for Estes to come through on their promise.

Bottom line on construction is this; it's not for the faint of heart. For anyone contemplating taking on this project, make sure you bring plenty of patience and be prepared for lots of frustration, especially if you don't have too much experience building complex rockets, like me. The most difficult task, aside from rolling the body tubes, was to fabricate the transition section. The largest piece in the transition section is a 3.3 inch arc that you must cut out of poster board. The angle of the arc has to be very precise, which was difficult if not impossible with my cheesy little protractor. Because of the size of it, you also need a compass that can do 15 inches of radius or have a computer that can draw it out on a plotter. Having neither the compass nor the plotter, my wife and I ended up using my little compass and a string. I tried five times before I got one that worked.and it still wasn't perfect. I decided that I would just fill a few gaps with some wood filler and move on.

Finishing:

Finishing is one area where I really lack good experience. Mono-colored rockets are about all I've done. The plans give very specific instructions on decal placement and size, however I didn't do any of it, just painted it according to the scheme from the picture that I had received from a friend.

Construction Rating: 4 out of 5

Flight:

Flight:

The biggest con for me was the prep time to get the rocket ready for launch. You don't just throw the motors in, a little wadding, igniters and then launch. I tested the wiring just prior to launch, installed a new Duracell and then the 'chutes. The plan calls 3 D12-0 and one D12-3 in the booster and a D12-5 or 7 for the sustainer. I used a 5 second delay because my rocket was a bit heavier than the stock plans. The rocket has an interesting method of igniting the second stage. One of the engine assemblies in the cluster has a piston and a micro lever switch inside of it. The piston, when the motor is installed, applies pressure to the switch and opens the circuit. You use a D12-0 in the switch tube. After the boost is complete, the ejection charge blows the motor out of the engine assembly, which in turn closes the circuit and sends the juice from a 9V alkaline battery to the igniter in the sustainer. During construction, make sure you take your time and follow the instructions carefully so that the piston works properly. I had to do mine twice before it functioned properly. To make sure that the motors fired properly, I used E matches with thermalite attached. A bit of overkill maybe, but I didn't want to mess up the launch (and the rocket) due to a misfire in the cluster or sustainer. I prepped the igniters the night before. The boost was stunning. My wife got a great video of the boost and the sustainer ignition. I've watched it at least two dozen times. The ematch/thermalite combination brought the sustainer motor up so close to the booster burnout that I couldn't detect any delay. I was told by one of my rocket buddies that it was the coolest flight of the day. Those few seconds were so good that all the time and frustration seemed to be fairly insignificant.

Recovery:

Things went awry after the sustainer ignition, as the parachute didn't deploy properly for the booster. The parachute separated, probably due to not using enough wadding. As a result, the transition section was destroyed and one of the fins popped off, but everything else was intact. The sustainer recovery was nearly flawless. However, landing on the hard ground in Eastern Colorado, I popped one of the elevons, which is easily repaired. The booster will be repaired soon and I will fly it again. The strength of the materials is a bit suspect so unless everything goes perfectly be prepared to do repair work on it.

Flight Rating: 3 out of 5

Summary:

Pros: This has to be one of the coolest rockets I've seen. It looks great and it flies great. It was the most challenging project that I've ever done. Cons: The strength of the materials require an absolutely flawless flight for you to not have to do any repair work post recovery.

Overall Rating: 4 out of 5

Sponsored Ads

|

|