| Manufacturer: | Semroc  |

(Contributed - by Matthew Bond - 12/01/09)

(Contributed - by Matthew Bond - 12/01/09)Brief:

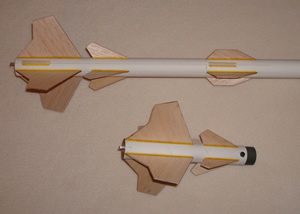

The Long Squire rocket was designed to meet the requirements of challenge #3 in the 2009 EMRR Challenge. The Long

Squire is a “Stage Bash”, a two stage rocket constructed from two single stage rocket kits, in this case, two

Semroc Squire kits. The name “FreeBird” comes from the fact that both of the Squire kits I used were actually

received as “free gifts” from Semroc as a result of my excessive spending on a couple of orders… The

Long Squire employs gap staging, and flies on 18mm motors. The booster uses tumble recovery and the sustainer comes

back under a 12 inch parachute.

Modifications:

As with all of my scratch built rockets, the first step involves some time spent playing around with a design in

RockSim. Since I had 4 body tube sections to work with I figured I would use 3 for the sustainer and one for the

booster. A couple of issues became apparent almost immediately. First: the Squire is near minimum diameter, and so I

would be limited to 18mm booster motors making weight of the overall package a concern. Second: with so many potential

fin configurations, I was going to drive myself crazy “tweaking” the design. I finally settled on a layout

that actually gives the impression of multiple stages, and decided not to worry about the weight issues right away.

Construction:

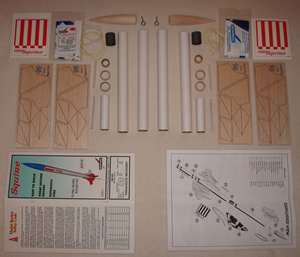

One of the reasons I chose the Squire kits as a starting point, is that they are presented as a kind of

“designers” kit, with two body tube sections and multiple fin layout options; heck the instructions show 12

different possible configurations! As with every Semroc kit I have ever seen, the quality of the components is first

rate. Each Squire kit contains the following items, so obviously I started out with two of everything listed here:

- Main Body Tubes 2x ST-890 (9”)

- Nose Cone BC-837

- Fins 1/16” Laser Cut Balsa - two sheets

- Motor Mount Tube ST-730 (3”)

- Tube Coupler HTC-8

- Centering Rings 2x CR-78 – heavy paper type

- Thrust Ring TR-7 – heavy paper type

- Standard Engine Hook EH-28

- Launch Lug LL-122 – 1/8” x 2”

- Kevlar® Shock Cord SCK-24 - 24”

- Elastic Shock Cord EC-118 - 1/8” x 18”

- 12” Unassembled Parachute Kit

- Small Screw Eye SE-10

- Decal Sheet

Assembly Instructions:

Construction of the actual rocket was fairly straightforward. Yellow wood glue was used except where noted. The biggest challenge during construction was the alignment of the 6 separate sets of fins. I chose to use the “That Looks About Right” (TLAR) method and even though there are some obvious misalignments between fins, they are all fairly straight, and there is enough total fin area that it all balances out. Overall I would rate this somewhere just beyond a skill level 2 effort.

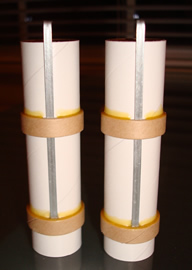

The motor mounts were constructed first, and are identical. The engine hook is inserted into the pre-cut slot and two centering rings slide over the tube and hold it in place. The aft centering ring is positioned 1 inch from the end of the tube and the forward centering ring is positioned over the end of the hook that sticks into the tube. I did not attach the Kevlar® shock cord to either mount as detailed in the original instructions since I planned on using the forward tube coupler for this. Thrust rings are installed against the forward end of the engine hooks. All centering ring to motor tube joints were reinforced with glue fillets.

Since one of the two tube coupler sections was to be used for the booster/sustainer interface, I needed another coupler to join the three sustainer sections together. After I figured out how long the booster body tube needed to be, I took a leftover section of body tube and cut a slot lengthwise to make another coupler section. I then threaded the end of one of the Kevlar® cords through the coupler section several times and knotted the end. Three 9 inch sections of body tube were joined to form the sustainer, and a 5.75 inch section was used for the booster with a tube coupler permanently installed in the forward end. The Squire does not come with a wrap-around template, instead and end view template is drawn in the instructions and you are instructed to stand the body tube up over this template to mark the position of the fins. I have never had any success using this method, as there doesn’t seem to be a way to mark all four fin locations without letting go of the tube, and losing your original position. I did the best I could, and again verified that this method doesn’t work for me. I used a section of small aluminum angle to extend the fin lines as required.

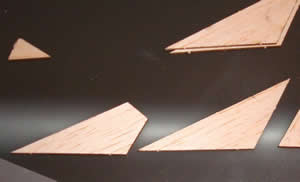

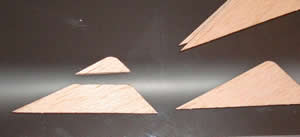

The laser cut fins were separated from their stock sheets and cleaned up with fine grit sandpaper. I modified the shape of the smaller fins and then match sanded all the similar shapes so that they were uniform. All fins were attached using a double glue joint. A light fillet of wood glue was also added to each joint. Two sections of launch lug were attached to the sustainer centered between the fins, 0.5 and 9 inches from the aft end. A vent hole was punched near the forward edge of the booster body tube to allow for pressure relief prior to the sustainer motor lighting. The eyelet was attached to the nose cone by screwing it most of the way in, removing it, adding a large drop of medium thickness CA glue and then screwing it all the way down. One of the only nits I have ever had with any Semroc kit is that sometimes the Kevlar®/elastic shock cords are a little bit short for my taste. By anchoring the shock cord near the front of the rocket and then tying all 4 pieces of Kevlar® and elastic together I can honestly say that the shock cord was long enough for me.

Finishing the FreeBird was accomplished with the overall weight of the rocket in mind. I did not do any filleting work with the Elmer’s Wood Filler (easy enough to justify on the basis of weight with 24 fins). All the balsa parts got a single coat of thinned down wood filler to hide the worst of the grain. A single coat of primer was applied. The body tube got a single coat of gloss white, and the fins were masked off in blocks and given alternating coats of red and blue. I applied the decals from both decal sheets, and although they were extremely easy to apply and set up well, the color was a little transparent, certainly not up to par with anything I had seen from Semroc before. Overall the finish came out nice, and if all the lines aren’t quite clean you can’t tell from the launch table.

Flight:

As mentioned earlier, the finished weight of the rocket was an issue due to the fact that I was limited to 18mm

motors in the booster. RockSim estimated the final weight (without motors) at 2.06 oz. The actual weight came in at 2.6

oz. and when I went back and re-ran the simulations, I discovered that every possible motor combination would need a

launch rod between 47 and 57 inches. Additionally, the rocket is over-stable, even with the heaviest motor combination

which would exacerbate any tip off issues. I went to the hardware store and got a 48 inch length of 1/8 inch steel rod

and headed to the field.

Since the sod farm was closed for the season I was limited to the small school field. For the first flight I

loaded up the FreeBird with a B6-0/A8-3 combination. Flight prep is standard. Both motors are installed under the

engine hooks and the booster is friction fitted to the sustainer. I had to use a single wrap of scotch tape around the

tube coupler to get a snug fit. Wadding and parachute are loaded into the front end and everything is ready. I had

lucked into a fairly windless day, and when the launch button was pressed the FreeBird boosted smooth and absolutely

straight. Staging was clean and the sustainer continued on its straight climb. Ejection occurred right before the

rocket stalled out and the chute deployed with no problems. Both booster and sustainer landed in the grass with no

damage. I loaded up the same motor combo and did it again, with another perfect flight. Feeling brave on a calm day I

loaded up a B6-0/B6-4 combo and sent it up again. There was definitely a little bit of tip off from the rod, but it

wasn’t too dramatic, and after clean staging the sustainer continued to a much higher altitude. Ejection was a

little early, but the chute deployed fine and once again everything came back on the field without a scratch. I even

flew the sustainer on a single stage B6-4 flight which also went of without a hitch. With the proper launch setup the

FreeBird is an outstanding performer and I am looking forward to the big field opening up in the springtime!

Summary:

I enjoyed the process of designing, building any flying this rocket. I liked the fact that it forced me to get out of

my “normal” zone and think about what I was building. The “Kit Bash” concept offers some additional

challenges in that you are working with a fixed set of parts, although since you get to choose the two kits that

shouldn’t be a problem.

PRO: A complex looking design which is actually a pretty simple gap staged 4FNC. Almost limitless combinations of fin arrangements allows for many individual styles.

CON: Near minimum diameter means limited booster motor selection, which translates into a total weight constraint.

Other:

One of my subconscious goals as I designed this rocket was to use as many of the pieces from each kit as I could.

This mind set actually played against me in the end since I was working with a weight constraint. The fact that I chose

to ignore the problem, and subsequently came up with a solution (longer launch rod) that allowed the design to work was

mere chance. I could have easily built a rocket that was too heavy to fly successfully in a two stage configuration. If

you’re not prepared to think things through then you live with the results. I got a bit lucky.

|

|

Flights

Sponsored Ads

|

|