| Construction Rating: | starstarstarstarstar |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar |

| Manufacturer: | Semroc  |

Brief:

In anticipation of Estes' announced re-release of A10-0 motors, Semroc has released a CHAD booster stage designed to

fit rockets utilizing their series 16 body tubes. One of the named rockets is the Semroc Centurion and I decided to

give my Centurion a booster.

Construction:

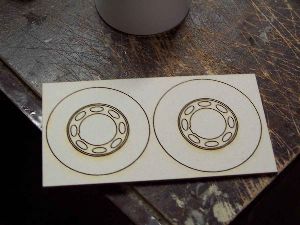

The kit consists of a pair of paper shrouds, an engine hook, a motor tube, a body tube, a pair of centering rings,

and a series 16 coupler tube.

Construction begins by cutting out the 2 transition shrouds from the provided piece of cardstock. The outlines are marked and its just a matter of being careful with the scissors. Once they are cut out, they are given a bit of a roll. White glue was then applied sparingly to the marked tabs and the ends were pressed together and set aside to dry.

Next up, the larger of the two centering rings is carefully punched out. Contained in its center, is a smaller centering ring for use with the motor mount. This was carefully removed and set aside.

The coupling tube was set down on the centering ring and centered so that an even but very small bit of ring was exposed all the way around. White glue was then used to tack down the coupler from the inside. When the tacks were stiff, white glue was used to fillet all around the circumference.

The motor mount was installed in the body tube by the simple expedient of pushing it in and aligning the aft ends of the tubes. The mount was installed with white glue.

The centering ring with the coupler tube attached was slid onto the body tube on the end opposite the engine hook and aligned so that it was straight and flush with the end. It was sealed in place with white glue and allowed to dry. Fillets were run around both sides of the ring.

After the coupler/tube joint had a day to set, it was time to start installing the transitions. The short one went on first and slid down to the coupler ring without any problem. It was seated with white glue and allowed to stiffen up some.

After a bit, the other transition was test fit. While the first one fit just fine, the second, longer one was a tougher case. I needed to sand away some of the smaller end in order to get it to fit over the tube. When I did get it on, I lined its seam up with that on the other transition and both were aligned with the engine hook. White glue was again used to set it in place.

The last remaining centering ring was punched out of its backing and slid over the motor mount inside the bell of the after transition. When it was even, white glue was again used to fasten it and the whole thing was glazed over from the inside with more white glue.

When the glue had set a little more, I took the booster and tried to give it a trial fit into the base of the Centurion. It was tight and will need some more sanding, particularly to get past some of the glue rivets I had originally installed. That would have to wait for another session though because duty called.

When I got back to work, I used a combination of #100 sandpaper and a rat tail file to smooth out the aft end of the ST16 tube of the Centurion. After a few fits and starts, the booster fit in just fine.

PROs: Easy to build.

CONs: None.

Finishing:

I masked off the coupler tube and then proceeded to prime the booster with Kilz.

When the Kilz was dry, I was somewhat surprised to see that it did not need much sanding. Usually its a bit blobby and speckly but that was not the case this time and after a single token swipe of #600 sandpaper, I went right to the painting. The recommended color is a gray but the only gray I had on hand was automotive primer and that's not what I wanted. I finally settled on a flaky metallic silver that looks more in keeping with a rocket nozzle to me. It took two coats.

I removed the masking from around the stage coupler and liked what I saw of the silvered nozzle but did not care too much for the glaring white of the inside. I wanted to do something about it even though it would rarely be visible.

I decided to hand paint the white with a Tamiya bronze paint. It took 2 coats and could probably have used a third for more even coverage, but I'm happy with it.

PROs: Easy to finish, looks good.

CONs: None.

Construction Rating: 5 out of 5

Flight:

The only recommended motor for the booster is the A10-0. I loaded one and put an A8-3 in the sustainer. It was a

windy day but I had waited too long and had to push the button.

The booster worked perfectly. It staged at a low altitude and was readily visible. Unfortunately, the sustainer motor had less oomph than it should have and the rocket arced over. It ejected on the ground. Even so, there was no damage and the booster was easily found.

A video of the flight can be found here.

Because of the wind, I decided not to fly it again that day but will be doing so in the future.

PROs: Staging that works at a height where it can be seen.

CONs: Estes may not make good on its promise to re-release the A10-0.

Recovery:

The booster is tumble recovery. It falls down and you pick it up. It works.

Flight Rating: 5 out of 5

Summary:

This is a great product that fills an under served niche. I hope it will long be available and would like to add one

to some of my other Semroc Rockets.

Overall Rating: 5 out of 5

Other Reviews

- Semroc Booster 16 By Hans "Chris" Michielssen (March 6, 2009)

This is the new Semroc A10-0T booster unit for the Centurion, Vega, and Goliath rockets. It is meant for existing, single stage rockets using the ST-16 (old Centuri style) body tubes. It will be interesting to stage a 13mm booster to a 18mm sustainer. I've never used a lower powered booster (A10) with a higher powered sustainer (B6 or C6, a A8 is also listed as a sustainer engine). ...

|

|

M.G. (July 23, 2009)

Sponsored Ads

|

|

M.G. (March 28, 2009)