Pemberton Technologies Screamin Green Meanie

Pemberton Technologies - Screamin Green Meanie {Kit}

Contributed by Claude Maina and Katy Maina

| Construction Rating: | starstarstarstarstar |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Pemberton Technologies  |

Brief:

This is a skill level 1, 24mm engine rocket that has a great look and some unique features. It is easy to assemble

and flies very well. The instructions are very clear and detailed with very good illustrations. The kit was a prize

offered by Pemberton Technologies for the July 2009 Best Rocket Competition on The Rocketry Forum and won by one of us

(Katy). The build and fly was a joint effort with Claude doing the build and Katy doing the finishing and flights, and

will be described accordingly.

- Construction:

9" Plastic Nose Cone - 1 - 4" 24mm Motor Mount Tube - 1

- Centering Rings - 2

- 9" BT80 Body Tube - 1

- 1" BT80 Body Tube (tube fins) - 3

- 1/8" Laser Cut Balsa Fins - 3

- 5' Kevlar®

Shock Cord - 1

- 16" Thermal Riders Parachute kit - 1

- Clay (for added nose cone weight)

- 1/4" x 1" Launch Lug - 1

- Wrap Around Fin Guides - 2

- Instructions

- Additional Components

- 3/8" scrap balsa

- 24" elastic shock cord

- 8.5" x 11" standard copy paper - 3 sheets

The kit is contained in a clear plastic bag with an unassembled parachute in a separate bag that has it's own instructions. The BT80 Body Tube was slightly out of shape when the kit arrived but it didn't present any problems during the build and eventually righted itself. I've read about PemTech 'Destructions' in different EMRR reviews and the 'Destructions' for the Screamin' Green Meanie lived up to their reputation. They are well written with good illustrations and are pretty funny. Although Katy didn't appreciate the clay snake gobbling up the cute, fluffy and tasty bunny> You'll have to buy the kit and read for yourself.

The body tubes are marked first with the two fin marking guides - one for the main body tube and one for the three fin tubes. I then filled in the spirals with diluted Elmer's Sandable Wood Filler and sanded the next day. While the wood filler was drying, I drilled a 1/2" hole in the base of the nose cone, inserted the clay and tapped it in the tip of the nose cone with a 3/8" dowel and let that dry for a few days. I then sealed the hole with a piece of masking tape followed by a coating of CA. The motor mount was next, which is just gluing on the centering rings, as there is no thrust ring or retainer clip. I'm used to both, so this was different for me; but there were good instructions on how to create an aft and forward retainer using tape. So, I went with it. The Kevlar® shock cord is tied on to the engine mount just below the fore centering ring. I did not feel comfortable with using just the Kevlar® shock cord. So I tied on a 24" elastic shock cord to the other end and used a swivel to attach the shock cord to the nose cone.

I did

reinforce the centering rings by gluing on rectangular supports between the rings and at the fore end using scrap

pieces of balsa. I did not put the supports aft of the lower ring, as this space would be needed to tape the engine.

I'm not sure if the additional support was needed but I had seen this technique described and wanted to give it a try.

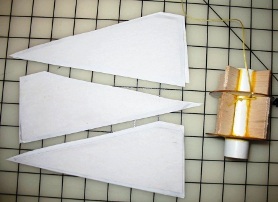

I made one more modification, which was also something I had seen described and wanted to try (Katy was not happy that

I was experimenting with her rocket!). I glued on paper supports to the balsa fins. I cut out 6 pieces of paper just

larger than the fins themselves. I then applied wood glue to one side of a fin and wiped off as much as I could with my

finger. I placed the cut sheet of paper on that side and pressed and smoothed it with my finger and a wood dowel. I

repeated this for the other side and then for the other two balsa fins.

I did

reinforce the centering rings by gluing on rectangular supports between the rings and at the fore end using scrap

pieces of balsa. I did not put the supports aft of the lower ring, as this space would be needed to tape the engine.

I'm not sure if the additional support was needed but I had seen this technique described and wanted to give it a try.

I made one more modification, which was also something I had seen described and wanted to try (Katy was not happy that

I was experimenting with her rocket!). I glued on paper supports to the balsa fins. I cut out 6 pieces of paper just

larger than the fins themselves. I then applied wood glue to one side of a fin and wiped off as much as I could with my

finger. I placed the cut sheet of paper on that side and pressed and smoothed it with my finger and a wood dowel. I

repeated this for the other side and then for the other two balsa fins. I let the fins dry overnight. The paper-coated fins

weren't perfect but came out pretty good with a minimal amount of ripples. I cut off the excess paper with a knife and

sanded the edges smooth. The sanding probably took a little too much off of the notch on the balsa fins that is there

to accept the tube fins, as the tube fins fit loosely onto the balsa fins. To remedy this, I used a small piece of

masking tape to hold the tube and balsa fins in place while the glue was drying. After the glue dried, I removed the

tape and filleted the tube fin/balsa fin attachment site for one side only - the side that would be away from the body

tube. While the glue was drying on the fins, I inserted the engine mount into the body tube as described.

I let the fins dry overnight. The paper-coated fins

weren't perfect but came out pretty good with a minimal amount of ripples. I cut off the excess paper with a knife and

sanded the edges smooth. The sanding probably took a little too much off of the notch on the balsa fins that is there

to accept the tube fins, as the tube fins fit loosely onto the balsa fins. To remedy this, I used a small piece of

masking tape to hold the tube and balsa fins in place while the glue was drying. After the glue dried, I removed the

tape and filleted the tube fin/balsa fin attachment site for one side only - the side that would be away from the body

tube. While the glue was drying on the fins, I inserted the engine mount into the body tube as described.

To attach the fins, I used Standard Rockets Assembly Tool (version 1.1). I'm not going to go into detail here on how it is used except to say that not using a thrust ring in the engine mount came in handy as I was able to use the Assembly Tool with the rocket inverted. A more detailed description will appear elsewhere. After the glue dried, I filleted each fin with 5-minute epoxy. I continued the fillet line through the tube fins (filleting the tube fin/balsa fin attachment site not filleted earlier). The next day I attached the launch lugs as described.

Finishing:

I (Katy) gave the entire rocket one coat of sanding sealer followed by light sanding. I then gave it two coats of

Rust-Oleum White Primer, sanding between each coat with 320 grit sand paper. I masked off the balsa fins and painted

the body and tube fins with Design Master Terra Rosa, four coats. I used a brush to get the inside of the tube fins.

The balsa fins were next with Design Master Violet, also four coats. I painted the underside with a brush with three

coats of Testors Gloss Black. The finish for all three paints came out smooth and so I did not sand in between coats or

after the final coat. After all of the masking tape was removed there were two areas that needed some touch-up with

Terra Rosa and this was done by brush also. I put on two decals - Screamin Meanie. The decals were made in MS Word and

printed on Laser Decal Paper (DecalPaper.com) Since the rocket wasn't green, we left out the 'Green' of 'Screamin Green

Meanie'. The purple lettering was chosen to try to match the fin color. Finally the rocket received four coats of

Krylon Clear Coat with wet sanding before the final coat.

Construction Rating: 5 out of 5

Flight:

The maiden flight took place at a CMASS October launch. The first flight was with an Estes D12-5. I taped the engine

to the exposed section of the engine mount tube with masking tape as described in the instructions. I used one sheet of

wadding placed inside the upper end of the engine mount tube and a 9" Nomex®

cloth to protect the parachute. I thought the 16" parachute supplied with the rocket would be too small, so I

substituted an 18" parachute. The flight was great. It went straight up. The nose cone ejected at apogee but the

parachute didn't come out and came it tumbled down. The nose cone stuck about an inch into the ground but there was no

damage. I think there was just too much stuff for the ejection charge to push everything out. The next flight was at

the next CMASS launch. It was a windy day so we went with an Estes D12-3 (taped as before) and a 24" parachute.

This time we just put in several sheets of wadding. This was another nice flight and this time the parachute deployed.

It landed a little hard (probably because it was windy), but there was no damage.

Recovery:

Flight Rating: 4 out of 5

Summary:

Pros:

This is a very nice skill level 1 kit and serves as a good transition to skill level 2. It has a unique look to it, easy to assemble and gives great flights. The instructions are very clear with good illustrations.

Cons:

A larger parachute than the 16" one supplied would work better and one of us (Katy) didn't like the snake eating the bunny.

Overall Rating: 4 out of 5

Other Reviews

- Pemberton Technologies Screamin Green Meanie By Matt Gillard (September 17, 2009)

Brief: I won this rocket from the March best rocket competition on TRF. I got the rocket sent super fast from the states to the UK. Thanks to Layne at Pemberton Technology for such a great prize. It's a hybrid of a 3FNC and a tube fin rocket. Construction: The kit comes in a plastic bag and has some of the best instructions I've ever seen in a kit, with step by step guidance, ...

- Pemberton Technologies Screamin Green Meanie By Bart Butler (May 6, 2008)

Brief: This is a Big Daddy-style rocket. It has a short, fat, mean look with tubes on the end of the fins. I love the tubes. Parachute is plastic with Kevlar ® shroud lines. Laser cut tubes and fins that made this a very easy kit to build Construction: Parts list: 1 Plastic nose cone BT-80 Ogive 1 24mm motor mount tubing (BT-50) 1 BT-80 (the instructions ...

|

|

Flights

Sponsored Ads

|

|