| Construction Rating: | starstarstarstarstar |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar |

| Diameter: | 1.33 inches |

| Length: | 23.38 inches |

| Manufacturer: | Squirrel Works  |

| Style: | Multi-Stage |

Brief:

The Tuber is one of my earliest purchases and has been sitting around for long time waiting for attention. It has

failed to get the attention because, over time, it migrated to the back of the racks as other rockets were placed on

the hooks. A few days ago, I noticed lots of pieces laying on the floor and investigated. The bottom of the Tuber's

package had given way and scattered some of the contents. I figured I better start building before anything got lost.

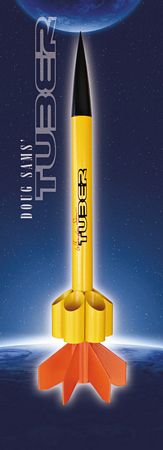

The Tuber is a two stage rocket. The lower stage features 6 conventional fins and it joins to a tube finned sustainer. Both motor mounts are 24mm. The booster tumbles and the sustainer comes down on a streamer.

Construction:

The first step in the instructions is to assemble a motor mount. Looking around in the bag, I could not find a 24mm

motor tube. I went and looked on the floor near where the bag was hanging and did not find any there either. So it is

that my build came to a screeching halt before I had done anything useful.

I have some BT-50 tubing and was willing to make my own to length but needed to know how long they should be so I posted a question on TRF. At the same time I posted the TRF question, I sent an email to Squirrel Works. It was a Saturday so I did not expect an answer until Monday at the earliest. The email was answered in less than 10 minutes and I had my answer. Both motor tubes should be 2.75" long. With that data, I got some scrap BT-50, marked two tubes, and cut 2 motor tubes to length.

One of the motor tubes was put into the bag for later use and the other had a thrust ring glued flush in the forward end. The motor tube then had 5/8" marked off from either end and the centering rings were glued into place. Both rings were filleted with yellow glue.

The kits comes with the makings of an Estes style tri-fold shock cord mount. I do not care for these and prefer Kevlar® harnesses so I tied a length of Kevlar® around the forward end of the motor mount and filleted it into place with more yellow glue. A notch was also cut in the forward centering ring to accommodate the passage of the Kevlar®.

When the glue on the motor mount had dried, the Kevlar® was fished through the motor tube so that it would not interfere with mounting. The inside of the body tube was then swabbed with glue and the mount was shoved into place with the end of the tube flush with the end of the airframe.

The Tuber comes with a wraparound fin marking guide, my preferred type. It was cut out, wrapped around the BT, and taped into place. The fin lines and lug lines were marked on the tube and then the guide was carefully removed and saved for use later with the booster stage. An Estes fin guide was used to lengthen all of the transferred lines.

The mitered tube fins for the Tuber come already cut. Even so, there is a handy wraparound template for them included. This would come in handy if I ever have to replace a tube fin but that is not its purpose. It is intended to wraparound the precut fins and be aligned so that the exact center line along the high point can be marked. Squirrel Works is to be applauded for this nice consideration. The tube fins were duly marked and the lines were also extended to the inside for easier seeing during placement. From there it was a simple matter to apply some yellow glue along the fin lines, line up the marks, and press the fins into place flush with the after end.

The balsa nose cone that came in my kit was about as nice as I have seen. I screwed the screw eye into the base, backed it out, squirted some glue into the hole, and reseated the screw. The cone was smooth enough that I decided to try and forgo the experience of sealing and sanding with Elmer's Wood Filler and decided to just drizzle on some thin CA to harden it up a bit and hopefully seal it. I might also add that the grain was dense enough that the CA was difficult to see since it did not absorb very much and darken the wood.

The tube fins had a chance to dry overnight and then the launch lug was glued into place along the line marked for the purpose. It was carefully examined with a short piece of 3/16" rod to make sure that the opening on the lug aligned with the space between adjacent tube fins.

Construction of the booster stage began with the motor mount. I retrieved the other piece of BT-50 I had

cut and found the thrust ring intended for the booster. It differs from the sustainer thrust ring in that it is made

from plywood instead of cardboard and is only 1/8" thick instead of 1/4". At first I wondered why it should

be different and then remembered some of the troubles I have had with staged rockets before. When the motors are taped

together and the thrust ring is behind the booster motor, my fat and clumsy fingers have had trouble managing the

igniter through the orifice. I could tell right away that having 1/8" less distance to deal with was going to be a

nice thing. This is another positive point for this design. In any event, the thin thrust ring was glued into place

flush with the end of the motor tube.

Construction of the booster stage began with the motor mount. I retrieved the other piece of BT-50 I had

cut and found the thrust ring intended for the booster. It differs from the sustainer thrust ring in that it is made

from plywood instead of cardboard and is only 1/8" thick instead of 1/4". At first I wondered why it should

be different and then remembered some of the troubles I have had with staged rockets before. When the motors are taped

together and the thrust ring is behind the booster motor, my fat and clumsy fingers have had trouble managing the

igniter through the orifice. I could tell right away that having 1/8" less distance to deal with was going to be a

nice thing. This is another positive point for this design. In any event, the thin thrust ring was glued into place

flush with the end of the motor tube.

The centering rings for the booster stage are identical to those for the sustainer but are placed just a bit differently. One was glued flush with the aft end (the end with the thrust ring) and the other was placed 5/8" from the forward edge. Both were glued and filleted with yellow glue.

While the glue on the motor mount dried, the coupler tube was located and marked at the halfway point. A ring of glue was then swabbed around the interior of one end of the BT-55 booster body and the coupler was pushed in up to the mark.

The CA hardened nose cone was sanded down, pronounced fit for the company I keep, and then tied to the elastic band that came with the kit. The other end of the elastic was then tied to the Kevlar®. With that, the sustainer was substantially complete.

I looked in my bag of parts and finally found the fin marking guide I had stashed from the sustainer. It was slid over the BT-55 booster airframe and the lines were transcribed and then lengthened with an angle.

The wrap was then removed and the motor mount was test fit. While the centering rings on the sustainer had no problem fitting into the sustainer tube, Both of the booster rings needed sanding. The forward one needed quite a bit. This is not to say that there was a defect. It's just that some just come fatter than others. The mount was glued in place with yellow glue and the thrust ring on the aft end.

The fins for the booster section are balsa and not tubes. Mine were in good condition and all still in the parent sheet. I used an X-Acto to free them from their bondage and then lined them up to sand their edges even. Once they were all fairly even, I ruined their evenness by sanding all edges except for the root into a round profile. It came out better than usual and I am confident that some day, I will be able to do this evenly.

Each of the fin lines which had been marked on the tube had a tick mark added to it 1/8" from the rear edge. This was to help align the backs of the fins. The fins were then glued into place with a double glue joint using yellow glue. When all had dried, they were filleted with white glue.

When the fins had dried, I checked to see how well the booster stage fit into the sustainer. I found it to be a bit tight but a little sanding took care of that. With that, the rocket was built and just awaited its livery.

Finishing:

Finishing of the Tuber began with sealing. It had been a while since I had used any Elmer's Wood Filler so I had to

mix up a fresh batch. That was then brushed onto the fins. While I was at it, I decided to hit the nose cone as well.

Both pieces were then allowed to dry for a day.

The next day, the nose cone sanded fine but the fins were still a bit gummy. I decided to give them an extra day. I went ahead and primed the sustainer with white though. It got 2 coats and the insides of the tubes got a hint of 2 coats.

The next day, the booster sanded fine and looked to be ready for priming. The booster got 2 coats of white primer. The primer was in turn followed by 2 coats of orange. The sustainer on the other hand needed just a bit of sanding after the priming. It then got 2 coats of yellow. When the paint had dried, I needed to do a little sanding on the tube coupler to perfect the fit but the rocket looked to be in good shape.

The Tuber comes with a single waterslide decal bearing the name of the rocket. The decal is of good quality and, to my mind, is clear evidence that even a simple, professionally made decal can do wonders to dress up a rocket. I think it looks great.

Construction Rating: 5 out of 5

Flight and Recovery:

As is my practice when flying a new rocket, I take it easy and build up the power over time. I also start in single

stage configurations when trying out a multi-stager. The Tuber was no exception.

I loaded a C11-7 into the sustainer and prepped it with dog barf. I added a streamer and set it on the

pad. The countdown proceeded and the Tuber lifted off quickly, straight, and true. There was no twisting or any

deviation from "up". Were it not for the tracking smoke in the motor, we all would have lost sight of it. As

it happened though, we were able to see it reach apogee and start back down just a bit before the ejection charge went

off. We saw the cloud of smoke and the body coming down. We also saw the streamer fluttering away in the light wind.

The rocket was not bothered by the wind, it just came down. Fortunately, it did so in a horizontal spin. When it hit

the ground, it did so near by. The nose cone was nowhere to be seen but there seemed to be no damage at all to the body

of the rocket. The shock cord, both Kevlar®

and sewing elastic, were wadded up in a blob terminated by the screw eye. A cursory examination revealed that the

threads on the screw had completely stripped out of the NC.

I loaded a C11-7 into the sustainer and prepped it with dog barf. I added a streamer and set it on the

pad. The countdown proceeded and the Tuber lifted off quickly, straight, and true. There was no twisting or any

deviation from "up". Were it not for the tracking smoke in the motor, we all would have lost sight of it. As

it happened though, we were able to see it reach apogee and start back down just a bit before the ejection charge went

off. We saw the cloud of smoke and the body coming down. We also saw the streamer fluttering away in the light wind.

The rocket was not bothered by the wind, it just came down. Fortunately, it did so in a horizontal spin. When it hit

the ground, it did so near by. The nose cone was nowhere to be seen but there seemed to be no damage at all to the body

of the rocket. The shock cord, both Kevlar®

and sewing elastic, were wadded up in a blob terminated by the screw eye. A cursory examination revealed that the

threads on the screw had completely stripped out of the NC.

Flight Rating: 4 out of 5

Summary:

This rocket was well thought out, well designed, well documented, and an example of "how to do it right".

Sometimes though, fortune figures its time to point the fickle finger of fate. Such was the occasion for me.

I will be ordering a replacement nose cone and rebuilding. Based upon performance, I wonder where I am going to be able to fly the full stack with any chance at all of recovery.

Overall Rating: 5 out of 5

Other Reviews

- Squirrel Works Tuber By Dave Bishop

Brief: 2 stage low power rocket. Sustainer is tube fin design Construction: The parts include: BT-55 sustainer and booster body tubes 6 Balsa fins for booster 6 Beveled tube fins for sustainer Balsa nose Cardboard coupler, centering rings and engine block 2 Mylar streamers This was my first Squirrel Works kit, my first staged rocket, and my first based ...

- Squirrel Works Tuber By Dennis McClain-Furmanski

Brief: Two stage sport model designed for 24mm motors with fins on booster and tube fins on upper stage. Construction: The kit contains: Long upper and shorter lower body tubes (BT-55 size) Balsa nose 6 laser cut tube fins (upper) 6 laser cut balsa fins (booster) Centering rings Tube coupler 2 engine blocks Elastic shock cord Screw eye 2 mylar ...

|

|

Flights

Sponsored Ads

|

|