| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Sheri's Hot Rockets  |

| Style: | Scale |

Brief:

Sheri's Hot Rockets Saturn 1B is a mid to high power (38 mm engine mount), 1/48 scale model of the 1960's NASA launch vehicle, best known for launching Apollo capsules into Earth orbit.

Construction:

The kit that I purchased includes the following parts:

- 1 main body tube, 5.25" x 24"

- 1 38mm engine mount tube

- 3.125" Service Module body tube

- 8 half round body tubes

- 2 sheets white cardboard stock

- 1/8" fiberboard stock (for centering rings)

- 1 Styrene sheet 0.010" thick

- 1 Styrene sheet 0.030" thick

- 6 sheets corrugated styrene wraps

- 10 pieces 1mm x 1mm square styrene detail strips

- 1 cast resin Apollo Command module

- 1 cast resin LES rocket

- 5 pieces 3/32" round styrene tubing

- 1 Shock Cord eyelet w/ blind nut

- 1 Shock Cord eyelet with screw end

- 1 piece ½" x ½" x 4" long square balsa stock

- 1 piece 3/8" round by 6" long hardwood dowel

- 2 piece 3/16" round by 4" long hardwood dowel

- 2 piece 1/8" x 1/8" x 3" long square balsa stock

- 1 piece 3/16" x 3/8" x 18" long balsa stock

- 1 piece 3/16" x 3/8" x 4" long balsa stock

- 4 small wood screws

- ½" round by 6" long styrene tubing

- 2 launch lugs ¼"

- 1 set decals

- Full size construction drawing

- Instruction Manual

- Template Manual

Sheri's kits do not include parachutes or shock cords--she recommends a 55-60" chute for the lower portion and a 36" chute for the upper portion.

I purchased my kit shortly after it was introduced. Sheri subsequently made some improvements, so I'll try to reflect both my building experience while pointing out where changes have been made. I had also purchased Sheri's Saturn V kit at the same time as the Saturn 1B. After I noticed on the website that the Saturn kits had been improved with more cast resin parts, I emailed Sheri asking if I could purchase the extra resin parts for the Saturn 1B and Saturn V kits. Sheri was happy to oblige. She'd upped the price of the Saturn kits when she improved it, so I paid the difference between the current price and what I'd paid. The additional parts for the Saturn 1B were:

- 4 display engine nozzles

- 4 "Reaction Control Systems" (the maneuvering rockets on the command module)

- Escape tower parts (I didn't use these)

- Some detail parts for the S-IVB stage

- New (improved) decals

The kit uses the same main body tube as her Little Joe II kit: big, heavy, 0.125" wall thickness, uncoated, and not cut to length. Fortunately, it's also very strong which proved fortuitous when I shipped the finished model (details later). I described Sheri's Little Joe II kit as being "old school", something you had to build not just assemble. Well, if the LJ II was old school, the as-purchased Saturn 1B kit was almost prehistoric. The centering rings for the engine mount and the forward bulkhead consisted of a piece 1/8" fiberboard, with appropriately sized circles "pre-drawn". That's right, it was necessary to cut out the centering rings and forward bulkhead. I used a jig saw and was pleasantly surprised at how well they came out. Fortunately, this is one of the areas that Sheri chose to improve, and the current kit includes pre-cut plywood rings.

The instructions for the basic assembly of the rocket are reasonably good (34 pages) plus several more pages of templates and patterns for making the various parts and pieces. The instructions for adding detail parts were weak--sometimes little more than "shape the part from balsa stock per the template", although anyone capable of building this rocket really doesn't need much more in the way of details.

As with the LJ II, the main body tube and couplers must be cut to length, and the coupler needs to be cut down to the appropriate slip-fit diameter. In addition, the fin can is a little larger in diameter than the main body tube, so it needs to be cut and re-glued with an appropriately sized filler piece added in to get the correct diameter. As recommended, I used a razor saw to make all the body tube cuts. The razor saw cuts through the thick body tube well enough but getting all the cuts straight takes care and patience.

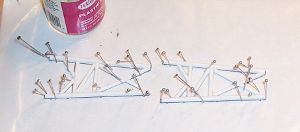

The exposed fuel tanks of the first stage are made up of half round body tubes (actually they are less than one half of a body tube--closer to a third). The half-round tubes are taped together with masking tape from the inside. When you've jiggled the assembly around enough to get it symmetrical, the top is glued to a main body tube centering ring, then the fin can is attached to the bottom using the engine mount tube for alignment. It was tricky to assemble the eight half round tubes into an even symmetrical assembly, however, my primary complaint about the half round tubes is that it's not scale. It's pointed out in the instructions that using the half round tubes saves weight, which is needed as this is a heavy rocket, but the half rounds are made from thick, heavy tubes. Using complete thin wall tubes of the appropriate diameter would give the proper scale appearance and wouldn't weigh any more than the half rounds. The fairing between the fuel tubes and the fin can is assembled from eight pieces of the 0.030" styrene sheet with each piece having to be pretty much custom fit. Mine went together OK, but again, care and patience, and lots of green putty is required.

Like the LJ II, the fins are built up construction, using the 0.030" thick styrene sheet. I'm a little surprised how well this works. The fins are relatively easy to construct, look good, and are impressively strong (like the LJ II, I filled the fins with foam, although I don't think it's really needed). Also like the LJ II, corrugated styrene sheets are used as wraps to simulate the external stringers. This is an aspect of Sheri's kits that I really like. It simply looks better than anything that can be done with vacuformed wraps. There are three sets of wraps for the S-IVB stage plus eight pieces that go between the fins on the first stage fin can.

The cast resin Apollo capsule is nicely detailed, but my example was not well cast with a number of small voids and other defects (it should be noted that the capsule in the Saturn V kit I purchased is much better, so perhaps I just got a bad one). However, it's big, solid, and heavy (nearly 8 ounces) although the instructions do say you can hollow it out without adversely affecting the stability. As noted above, Sheri provided me with cast resin parts for the escape tower, but I didn't use them. I'd already built the escape tower using the styrene tubing before the cast parts arrived, but I don't think I would have used them regardless. I kind of like building the escape towers although it is time consuming (and I've built enough Apollo escape towers over the years that I've gotten pretty good at it). On the other hand, the cast RCS modules for the service module were greatly appreciated as were the cast display nozzles and other detail parts.

An interesting detail is the use of 1mm x 1mm square styrene strips to add the 'ribs' to the service module. Gluing all the individual pieces and getting them aligned was tedious and time consuming, but the effect is striking.

An interesting detail is the use of 1mm x 1mm square styrene strips to add the 'ribs' to the service module. Gluing all the individual pieces and getting them aligned was tedious and time consuming, but the effect is striking.

The instructions do not go into much detail regarding adding the external scale details to the model. You need to refer to the full size construction drawing to see where everything goes, the instructions noting "You can add as much detail as you feel". With the large scale, an impressive amount of detail would be possible if you're so inclined (I wasn't).

Finishing:

As I discovered while building the Little Joe II, getting a good finish with the rough surfaced body tubes was tricky, so I tried something different that worked reasonably well. Prior to starting the assembly, I took some Elmer's Fill 'n' Finish, thinned it very slightly with water, and with my fingers, rubbed it into all the exposed body tube surfaces. After it dried, I sanded it down with 180 grit and then 300 grit sandpaper. The result was a surface not unlike a normal, coated body tube.

The large size of this rocket becomes quickly apparent when you start prepping and painting. There is simply a lot of area to finish. Combined with the fairly complex Saturn 1B paint scheme, it made finishing and painting the rocket a major undertaking. Masking around the fuel tubes to get the alternating black/white color scheme was particularly tricky, but there are limited options since the use of the half round tubes effectively eliminates painting the fuel tubes prior to assembly. As purchased, the decals in my kit were mediocre as they were printed on transparent self-adhesive vinyl. Fortunately this is another area that has been improved. The kit now includes a set of very nice waterslide decals from Space Model Systems which are a dramatic improvement. My model is detailed for the Apollo 7 flight (SA-205), which is probably the flight that most people would want to duplicate, but if you want to duplicate a different flight the decals include all the Apollo/Saturn 1B flights.

As originally purchased, I'd rate this kit as a 2 or perhaps 2 ½. However, most of the shortcomings have already been addressed (pre-cut centering rings, high quality waterslide decals, cast resin detail pieces and display nozzles) so I'd rate the current kit as about a 4. My primary remaining complaint being the less than scale appearance of the half round fuel tubes. Sheri did raise the price by $10 when she upgraded the kit, but in my opinion the improvements are more than worth the nominal extra cost.

Construction Rating: 4 out of 5

Flight and Recovery:

For recovery, I added two 36" parachutes attached to the booster by 10 feet of nylon strap shock cord. For the upper section with the Apollo capsule, I used a single 36" parachute, attached by about six feet of heavy Kevlar. I also rigged up a harness to hold the capsule and escape tower horizontal, using a snap swivel to attach to a screw eye that I'd embedded into capsule. The kit does not include any motor retention, so I added an Aero Pack engine retainer, my new favorite way of retaining large engines).

Due to the lack of high power launch sites locally, I elected to make the Saturn's first flight at NARAM 50, which involved shipping it cross country. Unfortunately, while the other four boxes of rockets and equipment arrived in good shape, the box containing the Saturn suffered severely. All eight fins where broken off along with several detail pieces, however that thick heavy body tube turned out to be an advantage. Suffering minimal damage (in contrast, a nice one-of-a-kind Nike Ajax model in the same box was destroyed--literally broken in half!) After I got through swearing, I took some CA and repaired the damage, after a little touch up paint, it didn't look bad.

This is a heavy rocket. Mine tips the scales at 4lbs 4oz with parachutes and close to 5 lbs flight prepped, so I decided to use a 29mm H RMS motor. My first choice was to use an AeroTech H128W-S, but I couldn't get anyone at NARAM to sell me one so I ended up using an H238T-S. I'd seriously considered not flying it after Walt Cunningham, one of the Apollo 7 astronauts, autographed the S-IVB stage. Plus, for some reason it took three tries before the RMS went together right (it also didn't help that I had a 24mm RMS cato earlier in the day for unknown reasons destroying a beautiful Q-Modeling Bullpup). By the time the countdown hit zero I was almost sweating bullets. The sudden kick of the H238 got the Saturn off the pad in a big hurry--no slow, majestic liftoff here, just a roar and it was gone. It flew near arrow straight to an estimated 500 ft with ejection very near apogee and the chutes deployed nicely. The rocket did suffer some damage at touchdown. It was obvious during the descent that the harness to hold the escape tower horizontal had failed (the snap swivel broke) so naturally the escape tower broke off when it landed nose first, and in a bit of bad luck, the lower section clipped the edge of a rock wall as it touched down, snapping off two fins. I suspect the H128W would have been better, as with the H238T everything simply happened too suddenly to really look good, but the rocket flew beautifully. I'd give it a full five stars. A different attachment for the horizontal harness is in order, but had the lower section missed that rock wall, I'm sure it would have been recovered undamaged.

Flight Rating: 5 out of 5

Summary:

After getting back home, I decided to properly repair the shipping and flight damage then repaint the entire first stage. (I didn't want to repaint the second stage, to retain Walt Cunningham's signature.) This required some new decals and once again Sheri was quite willing to accommodate my request. Alas, I made a troubling discovery while repainting the first stage. I've long used Krylon spray paint to paint my rockets. It was readily available, inexpensive, and most importantly user friendly. The key word here being "was". Apparently, Krylon has reformulated their paint and in doing so has lost some user friendliness. I painted the first stage gloss white using a can of the newer reformulated Krylon then mask off and sprayed the black using a can of old Krylon. This immediately resulted in the dreaded crinkle, a problem I'd never before experienced when spraying Krylon over Krylon. Long story short, I ended up having to completely sand down and start over again. It seems the new Krylon can be sprayed over new or old Krylon, but old Krylon cannot be sprayed over new Krylon. So if you use Krylon spray paint, beware that the reformulated Krylon has a different label (notable by more restrictive re-coating instructions) and a different semi-conical cap.

As I noted before, I was less than thrilled with the Saturn 1B kit that I originally purchased, but to Sheri's credit she apparently listens to her customers and the worst shortcomings of the original kit have been fully addressed in the current kit. So while there are a few items I'd still like to see changed (full round fuel tubes for the booster and coated body tubes all around), overall I give this 4 stars. If you like big, this one certainly qualifies at 55 inches tall it's the largest Saturn 1B currently on the market. With its Walt Cunningham autograph, this Saturn 1B has become too valuable to fly, which is a bit of a shame. I've been thinking about perhaps building another to fly and even looking into obtaining appropriately sized body tubes to replace the fuel tubes with full round tubes. But that'll wait, first I need to finish Sheri's Saturn V kit that is currently under construction (I'm hoping to fly it at LDRS 28).

Overall Rating: 4 out of 5

|

|

David N. VanMeter (November 21, 2011)

To further illuminate the problem outlined earlier...I made my mistake and now I have a weird looking Saturn 1B that I am halting construction on until I can figure out how to fix it. The kit comes with 8 pieces of tubing that have already been cut longways and are equivelant to slightly less than 1/2 round. The instructions say to tape these together to form a wobbly lobed tubed (my words, because that is what you get). They then to go to say that it should be centered and epoxied between the fin can and the upper tube that already had a centering ring in place. This does not come close to filling the gap between the tanks and tube at the top or bottom. My first though was, maybe I should have flattened them out a bit to expand the circle. That would mean that the tanks would intersect each other internally and that would not look right either. The only best answer is larger full tubes. The other problem that results from the scale issue of the fuel tanks is that the fairings between the outside of the film can and reaching the fuel tanks now has to be 3 tinmes longer to maintain the angle of the fine and reach the tanks properly. This looks odd as well. My plan is to rip off the transitions between the film can and the fuel tanks and sand it down to rid myself of excess adhesive, etc. Then I am going to use CAD or BRAIN and crude tools and figure out how big those tubes need to be, and recut them to fit over the existing tube structure which shouldnot add alot of weight. What a PITA! If anyone has any better ideas I am all ears and always appreciative. Yeah, I should have dry fit that one but it wasn't readily apparent until you had it together. Thanks !

Enrique Mertins (March 31, 2017)

Started building one of this rockets about a year ago (2016). I have modified quite a lot. I built my own paper tubes for the simulated fuel tanks, lightened all bulkheads and built a plastic transition for bottom part into fuel tanks. Long story short, most every kit component has been changed, modified or replaced. I'll probably use a H100, which according to OpenRocket will take this rocket to about 600'... I really like Saturn 1Bs. already built a Apogee's 1/70 and probably will scratch build a 1/32... version...

Paul Lunar (June 24, 2017)

Just finishing up one of these.. The cast epoxy details certainly reduce the work needed.. It builds kind of goofy but will bring out the artist in you as you work to correct its faults.

An H motor seems about right..

I junked the Card Stock and went to Tap Plastics for the transition shroud.. I'm writing a review now..

Sponsored Ads

|

|

David N. VanMeter (November 18, 2011)

I am well into the build of one of these and am annoyed by the scale problem you mentioned regarding the fuel tank tubes. What I did do to make their installation easier and make the whole thing more ridgid was that I discovered the tube the CSM is made from is the exact size to fit inside the fuel tube assembly, once it is taped together as instructed, and hold it ridgid. So I procured another tube, cut it to length, and inserted it into the tank assembly and glued at the contact points. Looks great but when added to the upper assembly there is a 1/4" gap all the way around, not the 1/8" called for. This was the case without the tube as well. In the pictures it looks like yours is right. What did you do? Its too late for me but others may benefit.

David N. VanMeter