Estes Laser Lance (3218)

By Steve Lindeman

2015-10-05

The "Laser Lance" looks like a military styled guided missile. Estes started releasing this kit in the summer of 2011 and my decal sheet was stamped 12/09/11 making it one of the early kits. This rocket is 20.3" long with a dia. of 1.64" and an estimated wt. of 2.8 oz. Recommended engines are: C11-3*, C11-5, D12-5, D12-7. Altitudes up to 925 ft. This was another rocket that I scored direct from Estes on there last clearance sale. My only regret is that I didn't buy more of these. At $3.79 a piece I should have bought at least a half dozen (original catalog price was $16.99).

Components

2015-10-05

Components are standard Estes materials and consist of the following:

A - 1 Engine Mount Tube

B - 1 Green Split Adapter Ring

C - 1 Black Engine Hook Retainer

D - 1 Engine Hook

E - 1 Engine Block

F - 1 Green Adapter Ring

G - 1 Body Tube (BT-55) 10.75"

1 Laser Cut Balsa Sheet

H - 9 Fins

I - 3 Fin Spacers

J - 1 Launch Lug Stand-off

K - 1 Launch Lug

L - 1 Tube Adapter

M - 1 Body Tube Nose Section (BT60) 3.25"

N - 1 Nose Cone

O - 1 Shock Cord

P - 1 Preassembled Parachute

1 Decal Sheet

Parts layout

Actual construction

2015-10-05

Actual Construction began almost two weeks ago but it has taken me this long to decide if I wanted to post this one or not as I didn't take all the photos that I should have. This was because at times I spent more time painting and building than taking photos plus I lost a number of photos due to operator error (inserted wrong memory card in camera). By rights this should have been only a two or three day build but because the fin assemblies are unusual they were a bit difficult to paint and I had some minor issues with them. Unlike most estes builds, this kit has you start by sanding the balsa wood and cutting out the fins instead of doing the motor mount first. I however started with the MM as this was the one area that I was going to modify. From this point on I merely referred to the instructions for reference as I jumped around a bit.

Motor Mount

2015-10-05

This is the one change I made to this build. I cut a small V notch in the top centering ring (F) before gluing it on and tied 12" of Kevlar around the MM and then slid the ring over it and secured it with yellow wood glue. I then tied a loop in the opposite end to attach 5' of 1/4" elastic for NC and parachute assembly. I then checked the length of the Kevlar by inserting it into the BT-55 tube to make sure it did not extend past the end of the tube. Once satisfied with the length I ran a large bead of wood glue around the back side of top ring to seal it all up.

Laser Lance Motor Mount

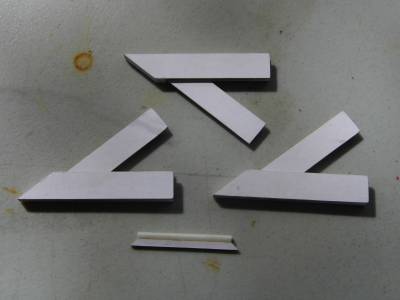

Fins

2015-10-05

At this point I started on the fins. The first step was to grab a clean sheet of printer paper and a glue stick to use on all balsa parts and paper coat them (these were the first set of photos I lost). Each balsa piece was treated with the glue stick on one side and then attached to the white paper. They were then cut out with an exacto knife and the process repeated on the other side. After that the fins were glued together. This was the first of several hurdles I had to overcome. I used a small plastic clamp to hold the pieces together at the front of the fin and then slid a scrap piece of balsa in the back part of fins and held it together with a clothespin. After all three fins were assembled they were set aside to dry overnight.

Fins paper coated & assembled

While they dried I grabbed the main BT-55 and marked it for all three fins and the launch lug (another lost photo).

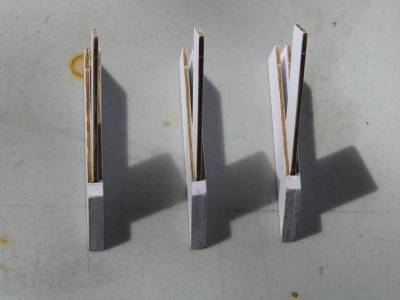

The following day I did the next step in the instructions and wrapped a sheet of 320 grit sandpaper around the main body tube and sanded the bottom of the fins to match the curve of the body tube. I then took 400 grit paper to the edges of all fins and smoothed them out. Next I masked off the bottoms of the fins and opened up the slots with an exacto knife. I did this in hopes of being able to spray paint between the fins. I then measured the bottom opening of the fins and marked them accordingly on the BT-55 tube for all three fins.

BT-55 marked (sorry for the fuzzy photo)

Initial Priming

2015-10-05

Next up I did the initial priming of the fins. These were done one side at a time with Rust-oleum 2X white primer and then allowed to dry outside (yet another photo I lost). I followed this up by masking off the BT-55 tube for the green paint between the fins as I knew this was going to be another problem area to paint once the fins were glued on.

BT-55 masked off

Nose Cone Assembly

2015-10-05

I next moved to the NC assembly. Nose cone and Tube Adapter were separated with a hobby saw and then the ends sanded smooth along with the mold lines. Plastic modeling glue was used to glue the tube coupler (L) onto one end of the BT-60 tube but not the NC. The NC I friction fit with green painters tape as I plan on using this rocket to pull double duty and serve as a payload rocket as well. After glue dried I went over the slight gap between Tube Adapter and BT-60 tube with Hobby-Lite and then set it aside to dry for an hour or so before sanding it smooth.

NC Assembly prior to painting

NC assembly was then given two heavy coats of Rust-oleum 2X white primer and allowed to dry overnight. The next day I sanded it down smooth and gave it another light coat of primer. NC was then set up outside to air dry and I jumped back to the fin assemblies.

Green Paint Added

2015-10-06

Here is where I encountered my biggest hurdle. As I said I had masked off the bottom of the fins hoping to spray paint between them. A quick trip to Wal-Mart and I picked up a can Rust-oleum Painter's Touch 2X Ultra Cover Paint+Primer Satin Hunt Club Green as a suitable color for a military style rocket. 2X Ultra Cover ain't the word for it. I had severe runs all over the fins and had to wipe most off with a rag. Needless to say this left a mess. Also had to run a scrap piece of balsa down between the fins to clear out the excess paint in the channels. After that I took a flat 1/2" wide artist paint brush sprayed with paint to touch up the edges of the fins. I then put them aside and moved on to the NC assembly.

Channel between fins painted

After learning a lesson with the fins I was much more careful in painting the NC assembly. I first went outback and found an appropriate size stick to hold the assembly without slipping. I then applied two light coats of green paint to it the then put it in my flag holder outfront on the porch to dry overnight (I do this quite often as the wife complains about the fumes if I let them dry inside). I then grabbed the BT-55 tube and sprayed the masked off slots with the green paint also. I then gave the BT an hour to dry and then removed all masking. At this point I left all parts outside on the porch to dry overnight. To my horror we got some sprinkles that night. Fortunately the NC assembly was the only thing that got wet and it really didn't get that wet as my flag holder is under a large tree that sheltered it. As a testament to my painting though there was no water damage to it. Have to admit in the shock of it all I forgot to take photos.

NC Assembly final paint applied

Fins & Launch Lug Attached

2015-10-08

Fast forward a couple of days. After allowing paint to dry completely I wet sanded all parts with 600 grit sandpaper and put them in the sun to dry for a couple hours. I then took the fins and after removing the tape from the bottom edges I sanded them one last time on the body tube to eliminate paint edges and then using yellow wood glue, I attached each fin and the launch lug to the body tube. After allowing another hour drying time I went over all seams with a bead of white glue. BT was then set in the sun to cure. That evening all was taken in for the night.

Fins & LL Attached

Priming & Painting

2015-10-08

The next day I started painting the BT. After the initial problem that I had with the fins I took my time at this point. I masked off the channel between the fins so as not to get any primer between them then carefully primed the BT with Rust-oleum 2X white primer.

BT Primed

Once primer was dry I again lightly wet sanded and then gave it a couple hours in the sun to dry. Once satisfied with the smoothness I painted the top half with Rust-oleum Ultra Cover 2X Satin blossom white. At this point rocket was again left to dry overnight.

Main white coat

The following day I masked off the top half of the BT and then the removed the tape from the fin channels before applying the Satin Hunt Club Green to the lower section and fins. After two light coats the rocket was again placed in the sun to dry for an hour. After that all masking was removed and rocket put up overnight to cure.

Green & White paint applied

Decals & Clear Coat

2015-10-08

Yesterday I applied the decals. There are only 4 or 5 decals deepening on which language you choose to use. The decals are printed in 3 languages with the exception of the lower half of the XERAT 42581 decal. These went on without any trouble. After giving rocket several hours to dry in the sun again, I applied two light coats of Krylon Matte Finish to the entire rocket to protect paint & decals. All that's left now is to attach the recovery system.

Decals Applied & Clear Coated

Recovery System

2015-10-12

On Friday the 9th I attached 5' of 1/4" elastic cord to the kevlar cord in the body tube and to the nose cone. I then attached the parachute to a snap swivel and then attached it to the shock cord. Rocket is now finished and ready for Saturday's launch.

Laser Lance Finished

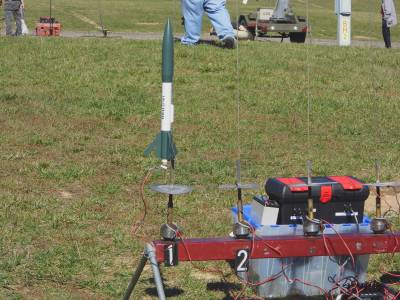

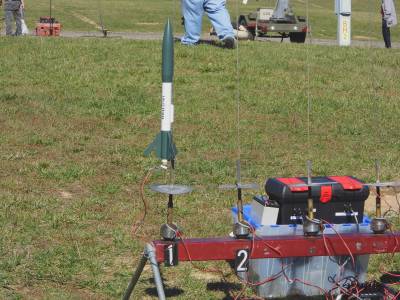

Flight & Recovery

2015-10-13

Maiden flight was on Saturday 10-10-15 with the J.M.R.C. folks down by Michigan International Speedway. Unlike the other dozen rockets that I loaded the night before I was not sure which motor I was going to use for this ones maiden flight so I didn't put any dog barf in it to ensure I didn't lose any out the bottom in transit. So when I got to the field I forgot to double check it after making the decision to make the maiden flight on a C6-5 with the 24/18mm adapter. Rocket was taken out to the pad and ignition wires hooked up. I then went back behind flight line and waited for rack to fill up and my flight to be announced. When our turn came up and button was pressed rocket jumped off the pad and flew to around 400' or so. Ejection charge fired after apogee. Unfortunately due to no chute wadding you can guess the rest. Chute was melted to inside of rocket and only about an inch of it stuck out of the tube. Fortunately she came down in a flat spin and this was a strong built rocket so on recovery I found only a small scratch along with the melted 'chute.

Maiden flight was on a C6-5 but I forgot to pack it with dog barf.

After recovering rocket I took it back to the car and removed the melted parachute. I then had to repair the shock cord as well as it was melted in three spots. After making repairs to the shock cord and replacing the parachute I loaded it back up, this time making sure I added the dog barf. For 2nd flight I opted to go with designed motor and loaded it up with a D12-5. This time it ripped off the pad and almost disappeared in the sky. I think I saw the chute deploy at apogee but hard to tell. Rocket drifted way, way, way down field in spite of the 4" spill hole that I had cut in the parachute. Hitched a ride with the mule driver to retrieve it. Found the rocket near the pond at the other end of the campgrounds. Recovery showed a couple of paint chips to 2 fins and a couple of tiny scratches in the NC.

Second flight on a D12-5 was perfect

Note: If it were not for the way the fins are designed I would consider streamer recovery on D flights as this rocket really gets up there. If you have a B field this rocket flies to about 400' or so on a C motor with an 18x24mm adaptor. Haven't tried a B motor yet but I think that should be OK as well.

Sponsored Ads

|

|