| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2010-02-09 |

| Diameter: | 0.98 inches |

| Length: | 12.30 inches |

| Manufacturer: | Estes  |

| Skill Level: | 1 |

| Style: | Sport |

Brief:

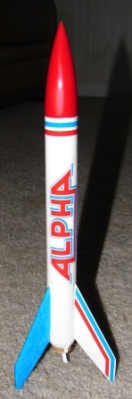

Estes classic Alpha is your standard 3FNC LPR model, probably in continuous production longer than

any other model rocket in history. It is a simple, straightforward build, listed as a skill level 2 build. Compared to

the model airplanes I fly, it's something a newbie could take on as a first project, especially if he or she had a

little guidance.

With its wide selection of motors and quick assembly, it's a perfect all-around rocket, and the body tube is large

enough to take up to a 24" parachute should you feel the urge to enter parachute endurance competition.

Construction:

The kit consists of:

- BT-50 Body Tube, XX" long

- PNC-50 blow-molded plastic nose cone

- Three laser cut balsa fins, 3/32" sheet

- 18 mm motor tube, 2.75" long

- 2.75" steel motor retainer

- BT-20 to BT-50 fiber motor mount adapter

- 1/8" white rubber shock cord

- 12" pre-assembled parachute

- Self-adhesive decal sheet

- 2 pages of instructions

The Alpha comes in a plastic bag, which seems to be a returning trend in Estes products. It is good to see that even Wal-Mart is starting to again carry higher skill level kits and that balsa fins and the like are again becoming oft-seem items.

A nice new advance is the addition of laser-cut fins (more on that later), which provide better cuts and speed finishing.

I started construction with the body tube and motor mound, per the instructions (which I'm not used to following, being

a model airplane guy who is used to not even having instructions), and decided to modify the model by extending the

motor tube 3/8" out the back of the body tube to allow a tail cone to be built around it. There was a slight dink

in the motor tube, but a quick coating of CA on both ends of the tube fixed this imperfection and ensured good wear

resistance. While I was at it, I hardened the nose end of the tube with CA to provide resistance against impacts and

mishandling. Total time for assembling the motor tube and installing it in the fuselage was less than 5 minutes.

I started construction with the body tube and motor mound, per the instructions (which I'm not used to following, being

a model airplane guy who is used to not even having instructions), and decided to modify the model by extending the

motor tube 3/8" out the back of the body tube to allow a tail cone to be built around it. There was a slight dink

in the motor tube, but a quick coating of CA on both ends of the tube fixed this imperfection and ensured good wear

resistance. While I was at it, I hardened the nose end of the tube with CA to provide resistance against impacts and

mishandling. Total time for assembling the motor tube and installing it in the fuselage was less than 5 minutes.

As a bit of personal whim, I glued bits of 3/16" balsa around the exposed end of the motor tube and sanded this

mess down into a small tail cone. This mod provides a nice effect, but should be considered with caution, as it places

the motor 3/8" aft of the design location, shifting the CG in the wrong direction. Before moving on, I hardened

the tail cone with CA and sanded the body tube thoroughly to minimize the spiralling groves in the body tube.

As a bit of personal whim, I glued bits of 3/16" balsa around the exposed end of the motor tube and sanded this

mess down into a small tail cone. This mod provides a nice effect, but should be considered with caution, as it places

the motor 3/8" aft of the design location, shifting the CG in the wrong direction. Before moving on, I hardened

the tail cone with CA and sanded the body tube thoroughly to minimize the spiralling groves in the body tube.

Fin installation comes next, and the paper tube marking guide provides accurate positioning. Some might find it

hard to use, but I had the marks on in less than 30 seconds. Now it was time to deal with the fins, and here I ran into

a squawk about the kit. The laser cutting does not go all the way through to balsa, so the fins must still be carefully

cut out of the carrier sheet. While this is ok, I've come to expect laser cutting to allow me to punch the parts right

out. Other than this minor issue, the fin stock was just the right density, and the laser cutting was clean, featuring

minimal burn marking. I planed and sanded the fins to a streamlined shape, hardened the tips with CA, and had the fins

all installed very quickly. I should add that the sharp tips are vulnerable in a hard landing, and I chose to round

them slightly. It's my opinion that sharp tips like these should never be considered if balsa construction is to be

used. I supposed a few bits of carbon tow would allow me to retain the sharp tips, but that wasn't on my agenda. We

should also note that the fin pattern on the instructions is

about 10% smaller than the supplied fins. I'll take the larger size, thank you. I attached the fins with CA and used

the same for filleting. With those long, sweeping fins, a hard landing could break the fins loose unless they are

firmly mounted. These shouldn't ever come loose with that CA on them.

about 10% smaller than the supplied fins. I'll take the larger size, thank you. I attached the fins with CA and used

the same for filleting. With those long, sweeping fins, a hard landing could break the fins loose unless they are

firmly mounted. These shouldn't ever come loose with that CA on them.

The instructions tell you to mount the launch lug just ahead of the fins exactly between two of them. A fine practice, but mounting it against one of the fins eases alignment and reduces drag. A further refinement modification was to slice the ends of the lug at an angle to further streamline the lug.

Estes is still using rubber shock cords, which I would prefer they stopped, but that's another story. I went ahead and used the supplied cord since I have had pretty good success with them in spite of my dislikes. The cord was respectably long, but a 50% length increase would be a very wise move. The paper shock cord mount is another beef of mine, but they can be made to be reliable if glued in place very firmly, which I made sure to do.

It was interesting to see that Estes is now supplying completely finished parachute kits. You need only organize the

shroud lines and loop them into place on the nosecone. The yellow and black checkering on the chute looks cool and

might seem like a high-vis scheme, but I'd prefer a solid color, preferably red, as it is visible from a much longer

distance than checkering. Still, it's a respectable chute, and the material looks stronger than what I've seen in the

past with Estes kits.

It was interesting to see that Estes is now supplying completely finished parachute kits. You need only organize the

shroud lines and loop them into place on the nosecone. The yellow and black checkering on the chute looks cool and

might seem like a high-vis scheme, but I'd prefer a solid color, preferably red, as it is visible from a much longer

distance than checkering. Still, it's a respectable chute, and the material looks stronger than what I've seen in the

past with Estes kits.

Total assembly time was about an hour and a half, and without my mods and extensive sanding, it could have been cut to 45 minutes.

Summary:

Great kit, good instructions, laser cutting is a nice finish.

Laser cutting needs improvement, and the shock cord and attachment could be re-done for better durability and functionality.

Finishing:

The nose cone has most of the flashing and mould seams removed, but I went ahead and sanded it as smooth as possible.

The plastic sands easily to a good finish.

The nose cone has most of the flashing and mould seams removed, but I went ahead and sanded it as smooth as possible.

The plastic sands easily to a good finish.

I gave the entire rocket a good coat of Krylon clear to fill in the tiny hints of sanding marks on the nose and fill the wood grain and other undesirable features. The result was pleasing.

After procrastinating a bit, I decided not to fly the model until it was completely finished. Out came the paint. I gave it several coats of Krylon satin white, which produced a decent finish, but failed to fill in the wood grain (will I ever learn to use sanding sealer?). Still, the result wasn't bad, though the tube spirals remained somewhat visible. I painted the nosecone in red gloss, and not having blue paint on hand, colored one of the fins blue by adhering blue tissue paper to it with spray adhesive and sealing the edges with CA. Yup, a trick from model airplanes. Minimal weight gain, too!

With the paint dry, I moved on to decals. Estes apparently supplies self adhesive decals with everything now. I'm not a huge fan, but being terrible with water slides, it's for the best where I'm concerned. Other than the fin decals being a little oversized, there were no issues, and the decals went on fine. Don't forget though, that with self adhesive, there's no second try!

After everything was finished, I gave the whole model a final coat of Krylon gloss, and oh how it shines! So in conclusion, my only qualm is with the oversized fin decals. Can't fault Estes for the wood grain thing, as that was my fault (the instructions say to use sanding sealer).

Construction Rating: 4 out of 5

Flight:

Estes recommends a long list of motors for this rocket. Basically it'll take nearly any 18mm motor you feed it. The

instructions say to use an A8-3 for the familiarization flight, but I didn't want to use up all of mine, so started

with a B4-4. The launch was straight as an arrow, no weathercocking despite significant winds. It probably went 800'

up, ejecting just a tad past apogee.

Estes recommends a long list of motors for this rocket. Basically it'll take nearly any 18mm motor you feed it. The

instructions say to use an A8-3 for the familiarization flight, but I didn't want to use up all of mine, so started

with a B4-4. The launch was straight as an arrow, no weathercocking despite significant winds. It probably went 800'

up, ejecting just a tad past apogee.

My second flight was on a calmer day, so I used a C6-5. Launch was again dead straight, with ejection right at apogee. I inclined the rod about 10 degrees to better center the rocket on the field (a good choice as I later saw), so it would have ejected prior to apogee had I gone for a straight launch. This model really gets up there on a C engine, easily making the predicted 1000+'. A very impressive show!

Recovery:

Recovery was flawless both times. The little 10" chute is a little marginal on visibility,

but let's face it, the only way to improve and still get a safe sink rate would be to make it day-glow red. The decent

rate is just right, though it would need a streamer for small fields. From a C engine, it takes roughly 2 minutes to

come back down.

In detail, on the first flight, with ejection just past apogee, the model drifted back overhead and was carried to the edge of the field. No damage from recovery, and the decent was stable, with just the usual rocking about. No dents from the somewhat short shock cord, either, and it did remain in good condition. With 5 sheets of recovery wadding, there was zero scorching of the chute.

The second flight was also very good, and I was able to catch the model as it descended down. Centering the trajectory on the field was a good idea, as it came down just short of some trees. Descent was very stable, with almost no rocking about by the end of the descent. I would say the chute is just right for this model in standard use, and seems very durable. The rubber shock cord is just fine, too, so long as you keep it out of UV radiation.

Flight Rating: 5 out of 5

Summary:

The Alpha built great other than my minor squawk about the fins and shock cord and finished out

looking just fine. Weight is respectable, resulting in a very high performance rocket that is still large enough for

easy flight preparation and motor installation/removal.

The flights are great and stable, insensitive to wind. Recovery system works great, and it will take virtually any engine you can fit inside it. There is sufficient room for a 24" chute if you're willing to let things get a little tight, so it's usable for competition, too.

Overall Rating: 4 out of 5

Other Reviews

- Estes Alpha By Ted Phipps

The Alpha has been around a long time. Combining simple construction (skill level 1), good looks, and great flying characteristics, it is considered a classic. Like most Estes kits, it comes in a plastic bag. Our kit had some pretty poor quality balsa, but some careful work with sandpaper and Elmer's Fill 'n' Finish resulted in a good looking rockets. The instructions and diagrams were ...

|

|

Flights

|

|

D.S. (September 1, 2000)

J.H. (July 1, 2001)

T.J.C. (September 17, 2001)

M.B.H. (October 18, 2001)

A.B. (November 18, 2001)

B.B. (June 2, 2005)

W.C. (June 14, 2009)

Sponsored Ads

|

|

P.B. (July 1, 1999)