| Manufacturer: | Scratch |

The Orient

Express

by Kelo Waivio

A study of low orbit/hypersonic passenger travel in

Foam-Core

(Or how to use foam core to make a light futuristic model rocket that doesn't

have a cylindrical fuselage)

The Orient Express is an experiment is using foam core for most of a rocket's structure. I had built a model using foam core with a box like fuselage earlier, but suffered a recovery system failure and is no more. The overall shape and look of the Orient express was inspired by a model of a hypersonic vehicle I saw in Power Transmission Design magazine. It was in a small article about some Marshall Space Flight Center engineers testing a mag-lev type of track for launching single stage to orbit vehicles.

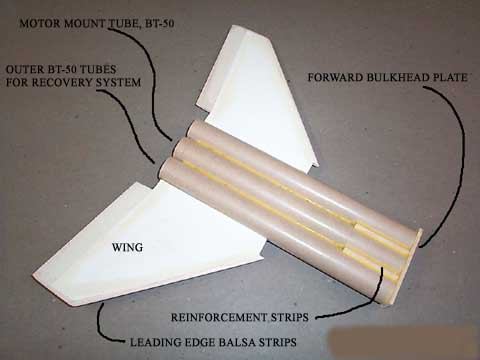

The fuselage is pretty much solid foam core consisting of two layers of half inch board with a layer of 3/16 inch board in between. The rear of he body is removed for three BT50 tubes. The central tube is the motor mount and the outer tubes are for the 2 16î chutes used for recovery. The wings are 3/16î balsa and are glued to the outer tubes and slid into the rear of the fuselage into a notch in the center sheet.

The three tubes are closed off at the forward end with a piece of 1/16î plywood. I used a paper punch to make the gas passage between the tubes before they were glued together. I beefed up this area with a balsa strip glued in the crotch between the tubes.

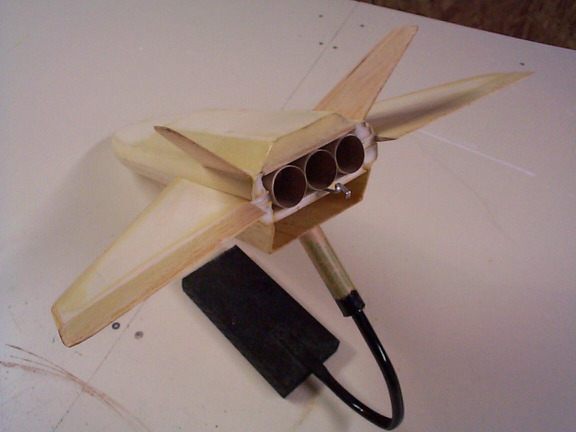

The section of 3/16î foam core cut out for the tubes was glued over the tubes on the bottom side and one section of half inch sheet was glued onto the top. Strips of 1/8î balsa were glued between the fuselage sides to give more gluing surface to these sheets. The 1/2î sheet was cut on three sides at a 45 degree angle, the back edge was left flat. The porous edges of the foam core was covered with Elmer's filler and sanded smooth. The whole thing got several coats of urethane varnish and was sanded between coats. (The results are OK, but there's got to be a better way.)

The two rudders were cut from 1/8î balsa and glued on the angled edge

on each side. The scram-jet duct is built up from 3/32î balsa sheet with

small strips on the joints on the inside for strength. I used Kevlar shock cord

anchors attached to each outer tube via the old slit-n-glue method and 2 feet

of 1/8î elastic for shock cords. I originally flew it with 2 12 inch

chutes but these are two small so I switched to 16î chutes which seem to

be just right.

So far the Orient Express has flown three times on D12-3's. This motor boosts it nicely, not too fast not too slow. I estimate it gets to about 200 to 250 feet with ejection just past apogee. It's CG using the precision finger-tip balance method is about half way back from the nose without an engine installed. I had to add weight to the nose, but I've since forgotten. I made a small hatch in the foam core, cutting out some of the inner foam but leaving the paper skin to cover up the weight after gluing it into the hollowed out space.

I haven't had the time to really work on a snappy color scheme. If I did I'd pick something along the lines of an airliner. I settled for a quick gloss white and flat black shuttle type scheme. Some of the flat black wraps around the leading edges of the flight surfaces and over the top of the nose. If I were to do any cosmetic modifications I would add some type of cockpit toward the front and possibly extend the cargo hold on the top surface farther forward, with it tapering to match the fuselage. The tip of the nose is also vulnerable, getting wonked on the first landing. Even with the larger chutes I'd glue a balsa or basswood block for the tip and shape to fit.

Dimensions:

Fuselage length 18 inches

Wing span 13 1/2 inches with a 5 1/2 inch root

Fuselage width 4 inches

Scram-jet duct is 3 1/4 inches wide, 5 1/2 inches long at the root and 1î

high.

Don't even think of asking me how much it weighs.

Top

Top Oblique

Bottom Oblique

Sponsored Ads

|

|